Introduction

This guide has been inspired by the Extruder Calibration article from Matt Harisson.

-

-

If you have set up a different extruder steps/mm value (e_step) than stock in the past we recommend resetting it to its default.

-

E step calibration isn't a reliable way to calibrate your extrusion because you are not measuring where it matters (what goes out of the nozzle). It is also a painful process to adjust e_step per type of filaments, the extrusion multiplier in PrusaSlicer is a lot easier to handle.

-

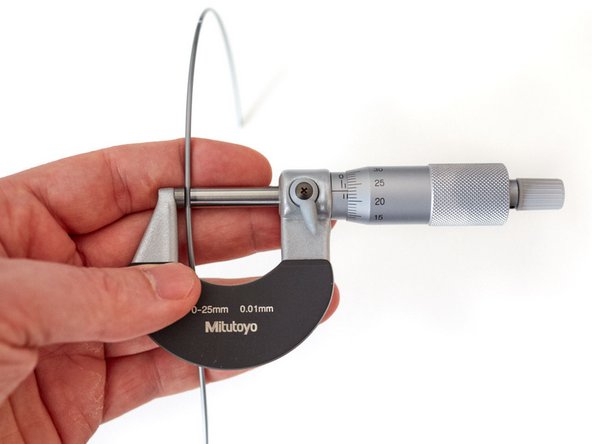

We recommend a micrometer instead of a caliper for the following steps. Calipers are not precise enough to measure such small values and a micrometer has a ratchet system made to apply same pressure for all measures.

-

If you still want to use caliper, make sure to always use the same pressure when you measure and don't press too strongly.

-

Tip: If you like to buy a micrometer, choose a quality one. We can recommend Mitutoyo 102-301 for its low price and quality. You can also check second hands market. Some recommended brands: Etalon, Mahr, Mitutoyo, Tesa, Starrett.

-

-

-

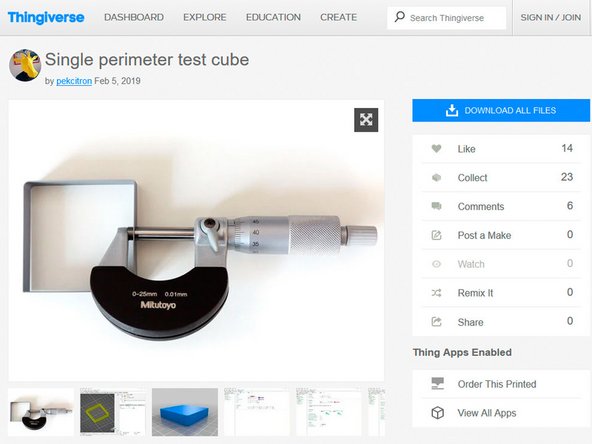

Download the calibration model from thingiverse.com/thing:3405991 or from github.com/gregsaun/.../test/cube

-

-

-

Measure your filament diameter with a micrometer. Write it on a piece of paper.

-

You could un-spool a little the filament, measure at several places and calculate the average.

-

-

-

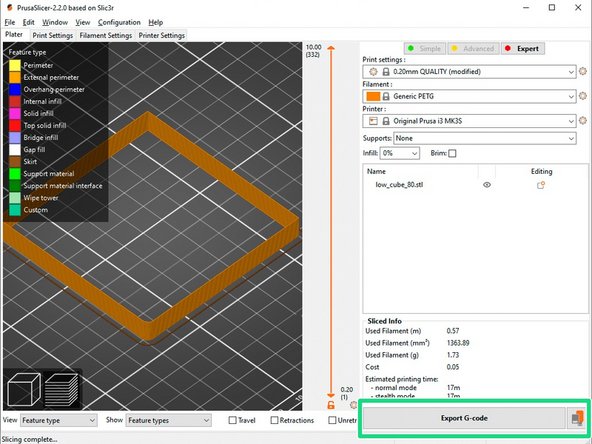

Start PrusaSlicer and load the calibration model. On the main page, select the following parameters:

-

Print settings: 0.20mm QUALITY

-

Filament: choose the filament profile corresponding to the filament you want to calibrate.

-

Enter your measured filament diameter into the corresponding input under filament settings.

-

Set your extrusion multiplier to 1.00

-

-

-

Set the following print settings:

-

Spiral vase mode (and accept dialog to auto-configure settings accordingly)

-

Solid layers Top and Bottom: 0

-

Slice the model and start the print.

-

-

-

Measure thickness of all the perimeters and calculate the average.

-

The most reliable measure is on the center of each walls as shown on the image.

-

-

-

Calculate your new extrusion multiplier using the formula on the 1st image. Here is an example:

-

Your original extrusion multiplier = 1.00 and your average perimeter thickness = 0.47mm.

-

Your are using a 0.4mm nozzle, so your target/expected extrusion width is 0.45mm.

-

Your new extrusion multiplier = (1.00 · 0.45)/0.47 = 0.957

-

Enter the new extrusion multiplier value in the filament settings page of PrusaSlicer.

-

-

-

Slice and print the calibration model again with the new extrusion multiplier value.

-

Verify the wall thickness with your micrometer. Repeat the previous steps if refinement is needed.

-

Do not change the printing temperature during these steps. Temperature might change the flow and therefore the extrusion multiplier.

-

Tip: The extrusion multiplier is generally constant for a whole spool (if you do not change temperature) but the filament diameter will change. Therefore, before slicing a part, measure the filament diameter you are going to use and enter it into PrusaSlicer.

-

-

-

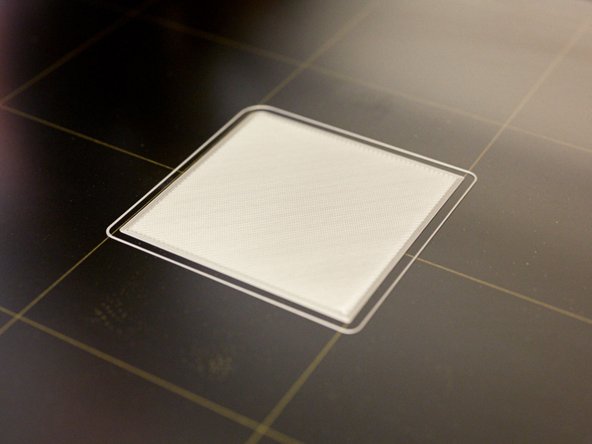

You can now more finely recalibrate your first layer.

-

You could print the first layer of the previous calibration model as a test.

-

-

-

Happy printing :)

-