How could I contact you?

- Github: github.com/gregsaun

- Github: github.com/bear-lab-3d

- Mastodon: @bear_lab@fosstodon.org

- Twitter: twitter.com/gregoiresaunier

- Discord: discordapp.com : greg_bear#0545 (I am active in 602 Wasteland server https://discord.gg/8fgzzSFyeV)

- Facebook: facebook.com/groups/prusabearupgrade

Who are the official distributors of the Bear Upgrade?

- 3D Boom (EU) : http://www.3dboom.es

- Lecktor (EU) : lecktor.com

- Makerparts.ca (CA) : makerparts.ca

- Ooznest (UK) : ooznest.co.uk

- PrintedSolid (US) : printedsolid.com

Where can I reach the Bear community?

Here are the places were the Bear project is the most active. Do not hesitate to ask if you have a question :

- Facebook group : facebook.com/groups/PrusaBearUpgrade

- Discord server of "The 602 Wasteland" community : discordapp.com/invite/hYUjSnW

- Twitter : twitter.com/gregoiresaunier

- GitHub : github.com/gregsaun

Who is supporting the Bear Project?

LDO Motors, Patreons, tippers, official distributors, etc. The full list here: Bear Supporters

I am having an issue with my printer and I can't find a solution in this website

You can reach the Bear community, we are always happy to help! Check the previous question to find where to reach the community.

Prusa has a detailed knowledge base where you can find information to fix issues. They also have how-to guide, recommendation for maintenance, PrusaSlicer help and assembly guides..

I can't find files or documentation, do you have a page to help?

If you are not sure which parts to print, which assembly to follow or what BOM applies to your upgrade, you should check the Project Overview page.

Which hardware and software is officially supported?

The Bear Project is not a company, it is a project that helps to make your 3D printing experience better. You are responsible for your upgrades and damage you could cause.

The Bear Project can only officially provide support for

- The original Prusa hardware and software

- The Bear frame from our official distributors

- The Bear extruder (with the calibration firmware used only for calibration and selftest)

- The BearMera extruder

You need to use our recommended filament and print settings because those are the conditions used to design and test our products.

We are providing optional parts for other extruders or hardware but we are not able to test all the combinations and so we can’t support them officially. Those optional parts might require different firmware on which we have no control and don’t know how well they are tested. Please refer to their manual, assembly instructions and support.

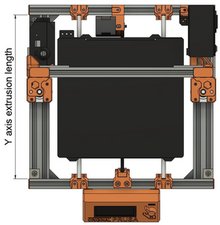

Which Bear frame do I have?

Measure the length of your Y axis extrusion as seen on the picture below.

- If the length is 311 mm long (±1mm) you have the MK2(S) or MK2.5(S) Bear 2.0 older shorter frame. You will find printed parts and all details in this page: optional_parts/bear_2.0_upgrade_mk2-2s-2...

- If the length is 331 mm long (±1mm) you have the MK3(S) Bear 2.0 frame which is the same frame as Bear 2.1 MK2(S), MK2.5(S) and MK3(S)(S+). Download the files from this page: Frame

Is the Bear X axis compatible with the original Prusa extruders?

The Bear X axis (X ends) are not compatible with the stock Prusa MK2.5S or MK3S extruder.

The Bear X axis (X ends) are compatible with the Bear Extruder, MK2.5 and MK3. They are also compatible with the BondTech Prusa upgrade extruder if you use the appropriate X-Carriage.

Is the Bear extruder compatible with the original Prusa X axis?

Due to a different belt path, the Bear extruder and X axis are matched to each other and cannot be used separately. As a unit, they are compatible with both Original Prusa and Bear Upgrade frames.

I am using the Bear MK3S extruder and I cannot pass XYZ calibration. How can I get it to calibrate?

This is a known issue which is caused by the difference in height between the stock Prusa MK3S extruder and the Bear MK3S extruder.

There are two workarounds for this issue.

- Firstly, you can flash temporarily an older MK3 firmware, such as 3.7.1, and perform the XYZ calibration. Once calibration is passed, flash the MK3S firmware of your choice to access the full functionality of the MK3S.

- Secondly, you can use our Bear calibration firmware. Make sure to follow the assembly instructions of the Bear extruder, we will guide you carefully. In case you are searching for a direct link, you can find the releases here: github.com/bear-lab-3d/Prusa-Firmware/re...

Disclaimer: The use of any non-Prusa firmware linked here is provided “as is” without warranty of any kind, either expressed or implied, and is to be used at your own risk. We encourage people to use genuine products and firmware from Prusa.

Where can I find the Bear X axis and carriage for Bondtech extruders?

Here: Bear X carriage for Bondtech Prusa Extruder

Where can I find the BearMera for E3D Hemera?

Here: BearMera Extruder

Should I use a smooth or toothed idler on the Bear X axis?

The Bear is designed to permit use of as much of the original hardware as possible. As such, you may use the original 20T smooth idler.

However I would recommend that you choose a Gates 2GT, 20T, toothed idler with dual bearings, to replace the Prusa supplied, 20T smooth idler with a single central bearing.

We recommend genuine Gates idlers from E3D-Online.

What filament should I use for my printed parts

All our project comes with recommend filament type in the print settings, be sure to check those. In general, we use plain PETG (without carbon fiber nor glitter).

Plain PETG is what we use to test and develop our parts so if you use something else you might experience various issues (brittleness, rusting, flammability, etc.). PETG is also the most reliable filament you can find in term of print quality, accuracy, mechanical properties (not too brittle but not too flexible), ease of use and flammability.

For extruder's shroud (fan ducts) we recommend ABS over plain PETG as it needs more heat resistance.

Please consider recycled filaments, here are some brands for inspiration :

- 3DJake rPETG

- Filamentive PETG

- Filaments.ca Recycled PETG

- FormFutura ReForm rPET

- GreenGate3D PETG

- Proto-pasta Simply Black PETG

- Prusament PETG Recycled

- Re-Pet 3D PET-G

Warning:

- Additives such as glitter are reducing the quantity of plastic in your filament. This could change the mechanical properties and reduce layer bonding

- Glitter could rust metal part as they are sometimes made of metallic flakes

- A filament with too much carbon fiber can make the parts too brittle. Adding more perimeters or infill will not always solve this issue.

- We don't know if additives like glitter or carbon fiber can make your part more flammable so we recommend to test this first and use at your own risk.

Those are only our recommendations and for sure everybody is free to test and use what they like. Don't hesitate to share your feedback as well, we are always happy to test new things and improve our work

My screws and nuts are floating, is there a problem with the design?

All Bear parts are designed to acomodate standard hex and square nuts with a snug fit. If you are finding that your nuts aren't staying secured or are spinning within their socket, this is most likely caused by under extrusion in your prints. Refer to our extrusion multiplier calibration guide here: Extrusion multiplier and filament diameter

Is there a MK2S version of the Bear Extruder?

There is no official version of the Bear extruder which suits the MK2S. We recommend to use the Original Prusa MK2S extruder.

However, there is a community developed version, from Ringo1908, that allows you to use the MK2S hardware - hobbed drive gear, bearing idler and PINDA probe, in an extruder based on the Bear Extruder. You will need a 12V, 2-wire, 4010 fan for this extruder to replace the stock 3010 fan.

https://www.thingiverse.com/thing:325212...

Do you have build videos?

3DMN (Joseph Casha) has made a serie of build video for Full Bear 2.0 MK3 with Bear extruder 0.6.0-alpha : https://youtu.be/9ttsCbnQWk4

Chris Riley has made a serie of live build of Bear 2.1 MK3S with original Prusa extruder : https://youtu.be/oEOYfAPcm9Q

Do you have a full BOM to build a Bear from scratch?

Chris Riley and 3D Gussner have build a full BOM available here

Where can I find the source files?

In our Github you will always find a "src" or "source" folder which contains the source files of our projects (generally Fusion 360 files). We are also sharing STEP files for interoperability between CAD software.

What pulley and idler size I should use?

- Pulley on the motor size is 16T for both X and Y axis

- Idler on tensioning side is 20T for both X and Y axis

Which type of grease or oil should I use?

We recommend to use lithium based lubricant that has a viscosity between 50 and 100mm2/s at 40 °C, NLGI class 2 and a thermal resistance of 100°C or more.

Pack a bit of grease inside the bearings (don't pack it fully) before assembly and continue to put a dab on the smooth rods 2 times a month.

3 Comments

Hello, I just upgraded my Prusa to have the Bear frame. I am having the issue that the Hot-end rotates inside the assembly. I tighten up all screws, but still, at some point in the print the X-axis gets shifted and the print gets off-axis. Any recommendation as to how to solve this?

Alvaro Uribe - Reply

There is no Genuine Gates idlers - it was checked with EU distribution center.

Gates LLC doe’s not provide any idles or gears - E3D sells gears from chines Supplier and cheat his customers.

Similar situation is with Gates Belt offered by E3D - this is a Gates Unitta (offered on chinese market) belt - totally different than original Gatess LLC belt.

Greg Siek - Reply

Hi Greg,

Just to clarify your misconceptions, Gates Unitta is the Asia wide joint venture between Gates Corporation and Nitta Corporation. They manufacture and supply genuine Gates parts, including 2GT belts and fittings. Gates LLC (US/Europe) no longer make 2GT belts or fittings.

So E3D source their, genuine, Gates 2GT belts and parts from Gates Unitta. Anyone wanting to supply Gates 2GT belts (eg. Prusa), will have to source them from Gates Unitta.

Welcome to the global economy.

Dave Ogles -