-

-

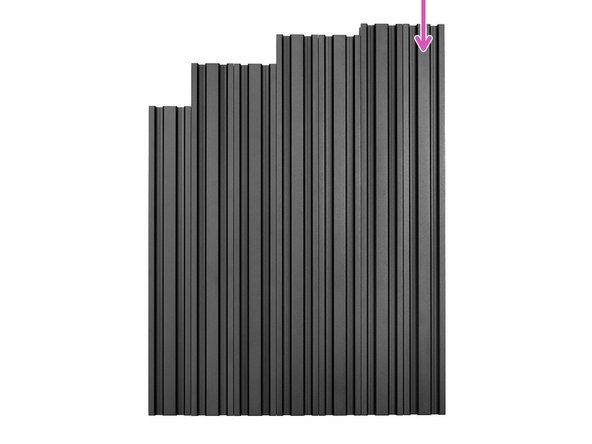

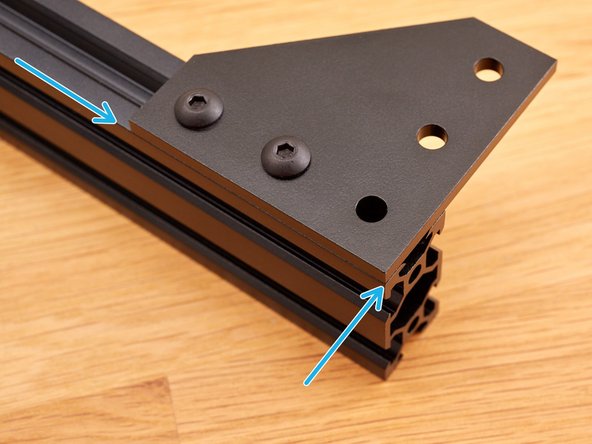

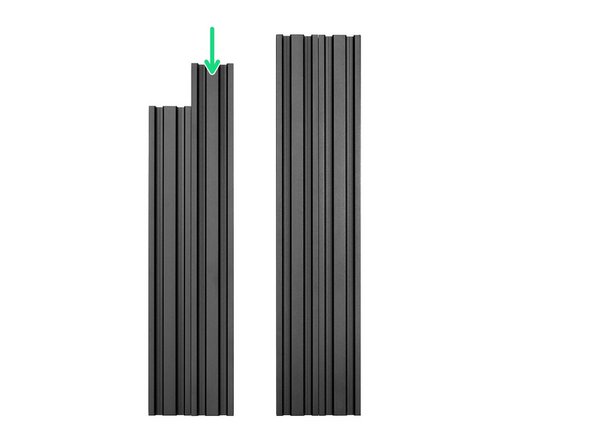

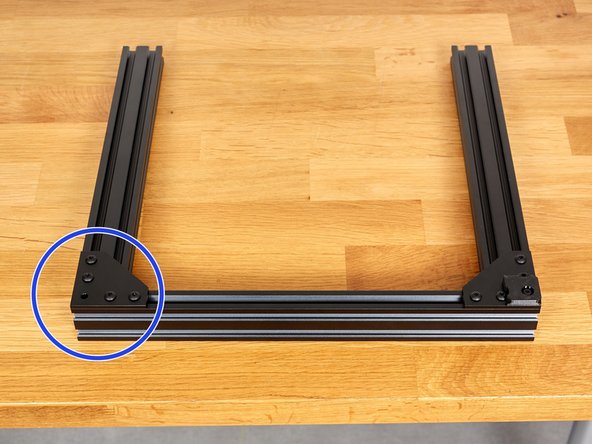

We are using t-nuts to bolt parts and plates on the extrusions. Those t-nuts are slide inside the extrusion.

-

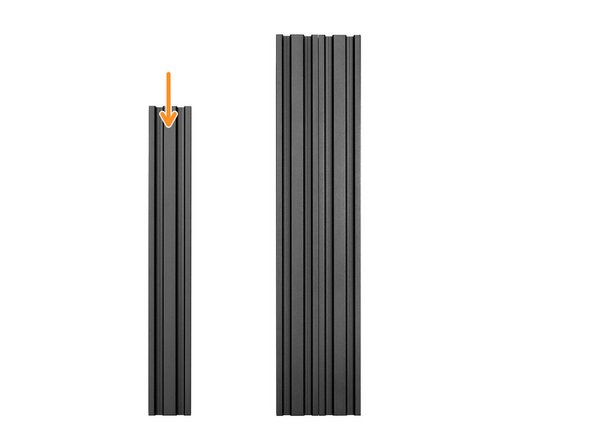

Bear Upgrade 2.1 comes with custom t-nuts that can be inserted in only one direction.

-

If you use Openbuilds hardware or other kits your t-nuts needs to be inserted in a certain orientation.

-

-

-

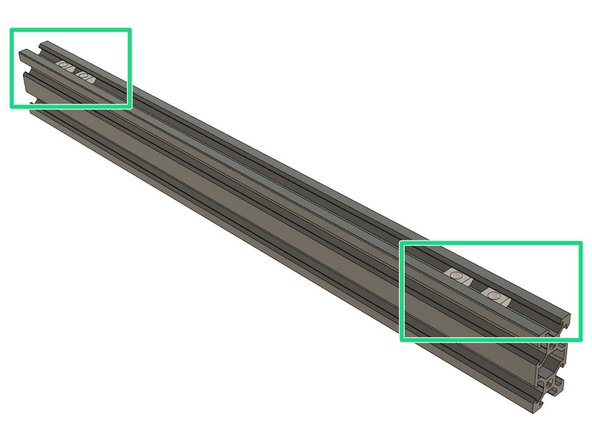

Take one of two longest extrusions. It is 370mm long.

-

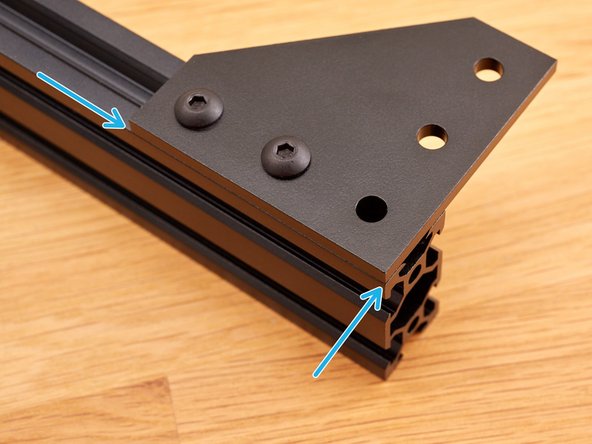

On the 20mm face of the extrusion, slide 2x t-nuts on each side (4x t-nuts in total).

-

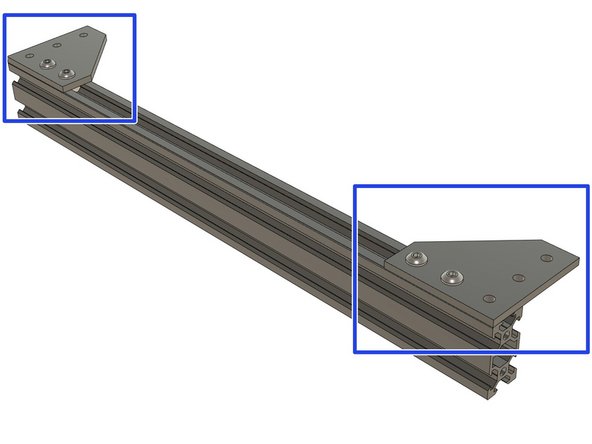

Bolt two plates on the t-nuts using 4 M5x10mm screws. Do not tighten them fully yet.

-

-

-

Take your time with this step, the plate needs to be well flushed as it could affect the rest of the assembly.

-

Make sure the plates are flushed with the extrusion and tighten strongly the M5 screws (no more than 4.5Nm if you have a tool to measure).

-

To help aligning the plate while tightening you can use a second plates and a flat surface.

-

Then press the plates against extrusions and the flat surface with one hand and tighten the M5 screws.

-

Repeat this with the plate on the other side of the extrusion.

-

-

-

Take the longest extrusions. It is 370mm long.

-

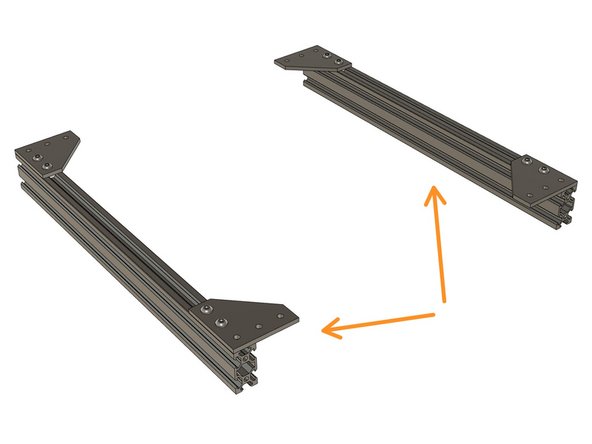

Repeat Step 2 and 3 on this extrusion. You should now have two identical construction.

-

Double check that all your plates are correctly flushed with the extrusion as it could affect the rest of the assembly.

-

Verify that both extrusions are 370mm long.

-

-

-

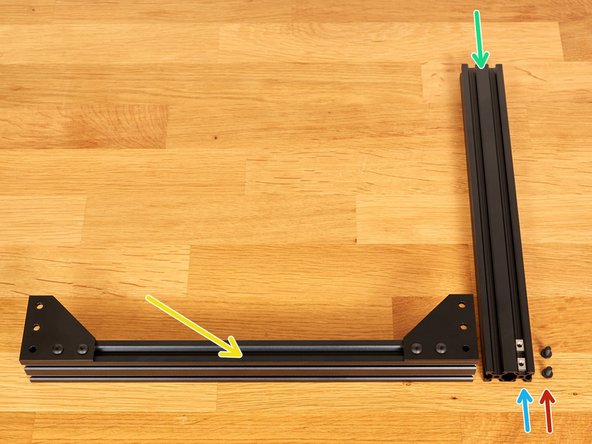

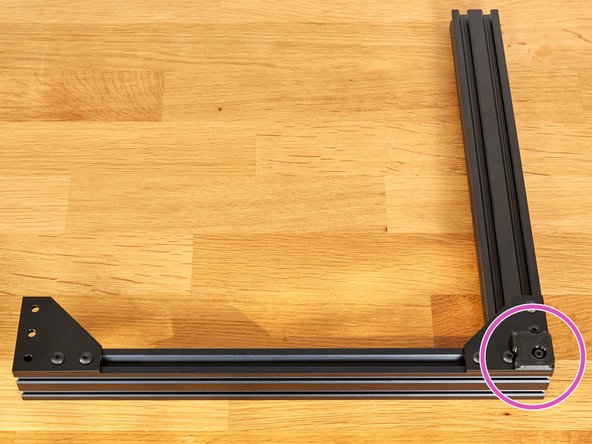

Take one the two middle length extrusions on the pile of not used yet. It is 331mm long.

-

Prepare the following parts:

-

1x previous extrusion and plate assembly

-

2x t-nuts. Slide them in the 331mm extrusion as shown on the picture.

-

2x M5x10 screws

-

Assemble the corner with the M5 screws. Do not tighten fully yet, it will need some adjustment first.

-

-

-

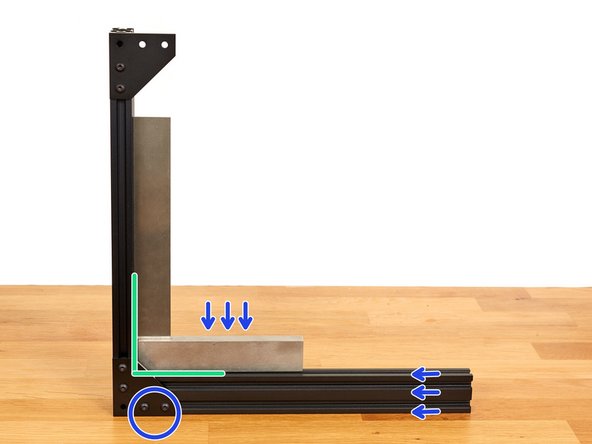

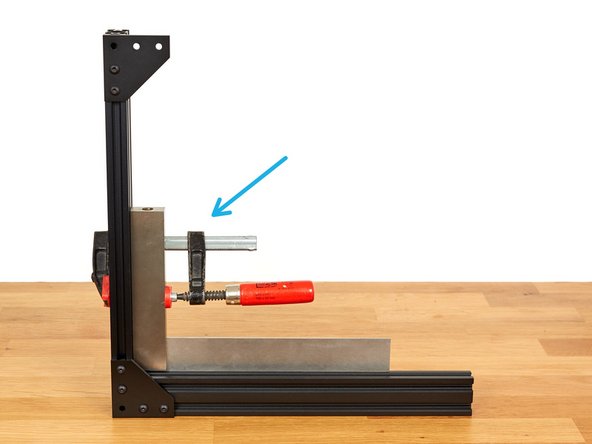

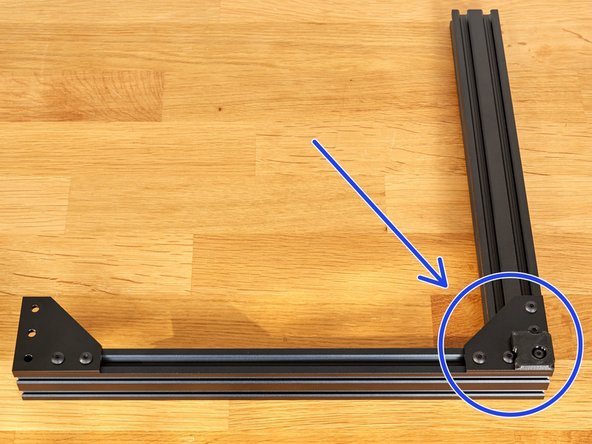

Take your time for this step, it will be a reference for the rest of the assembly. Ask the help of someone else if you feel the need of a third hand.

-

Make sure you are on a flat and plane surface.

-

Place the assembly vertically.

-

Be careful to not let fall down the assembly.

-

Square the extrusions with a square.

-

Apply pressure in the directions shown and tighten strongly the two M5x10 screws.

-

This step can be easier if you have a clamp. You can then secure the thicker side of your square to the vertical extrusion as shown in the 3rd image.

-

Verify that the assembly is still square after tightening.

-

-

-

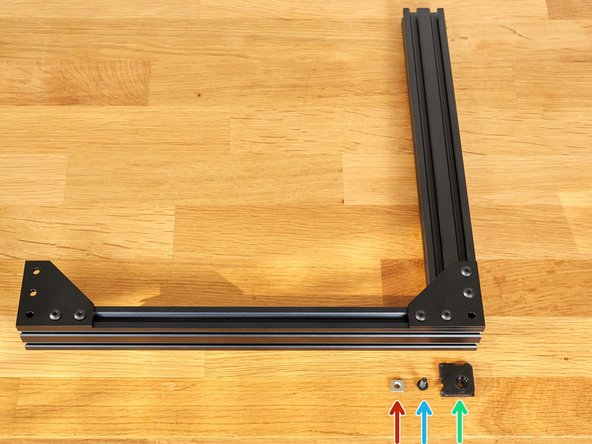

Prepare the following parts:

-

One t-nut.

-

One M5x12 screw

-

One 3D printed foot (foot.stl)

-

Slide the t-nut from the right side.

-

Attach the foot with the M5x12 screw. Tighten strongly.

-

-

-

The corner with the foot is now considered as a reference. In case of doubt during the next steps, you know that this corner is perfectly square and you don't have to touch it anymore.

-

You can double check that the five M5 screws are all strongly tightened. Do not exceed 4.5Nm.

-

-

-

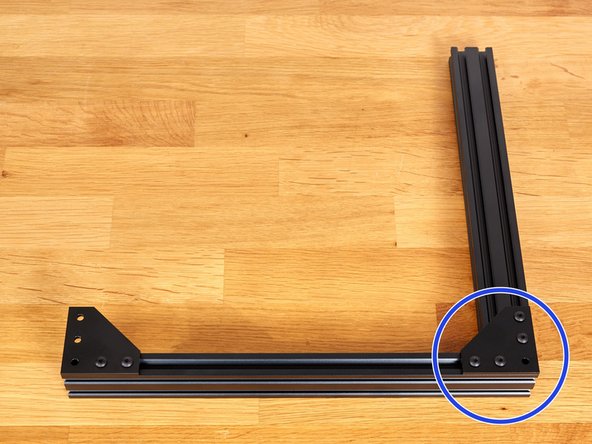

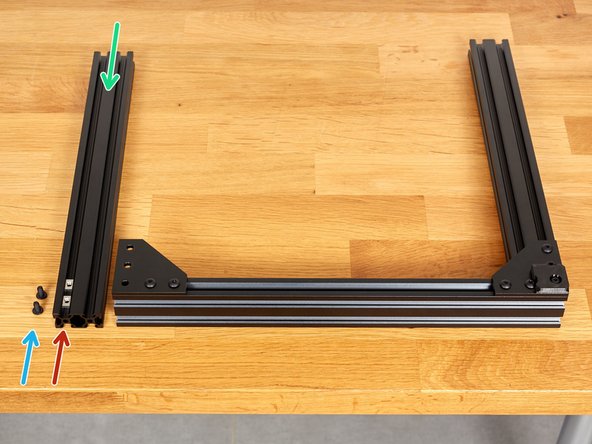

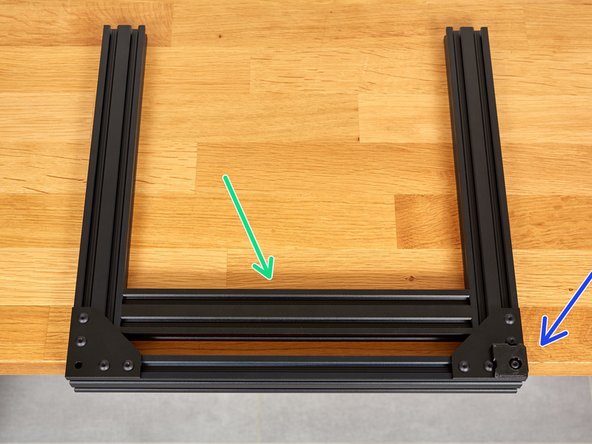

Take one the last middle length extrusions on the pile of not used yet. It is 331mm long.

-

Prepare the following parts:

-

2x M5x10 screws.

-

2x t-nuts. Slide them in the 331mm extrusion as shown on the picture.

-

Assemble the 331mm extrusion with the M5 screws. Do not tighten it fully yet, it need to be able to move a little bit.

-

-

-

Take your time with this step.

-

Take one the smallest extrusions on the pile of not used yet. It is 290mm long. It will be used for reference.

-

Place the assembly at the end of a table

-

Carefully insert the 290mm extrusion in between as shown in the 2nd image.

-

Be gentle with the 290mm extrusion or you might mark permanently the assembled extrusions.

-

Apply pressure in the directions shown and tighten the two M5x10 screws. To not overtighten them for now, only firmly secure the extrusion. movement of the extrusion.

-

You can now remove the 290mm extrusion carefully and reserve it for later.

-

-

-

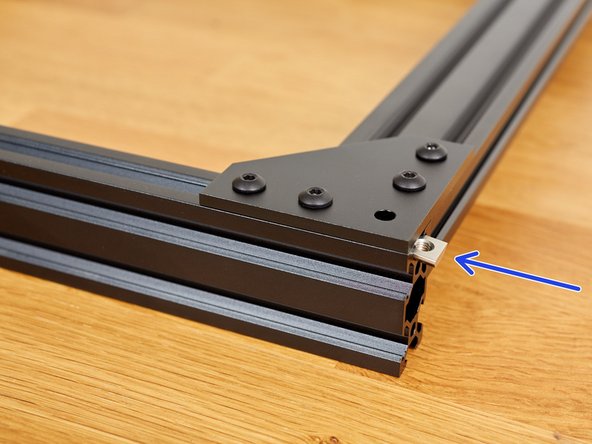

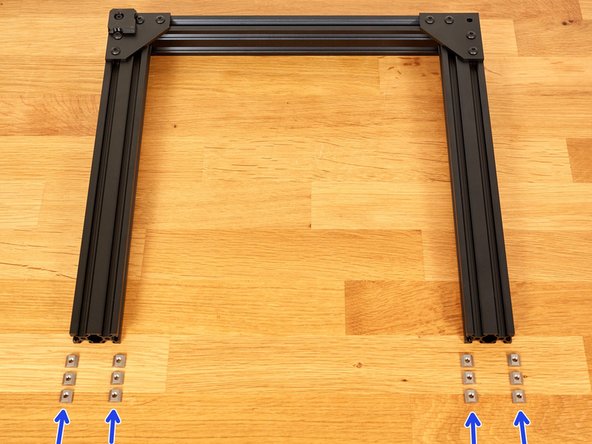

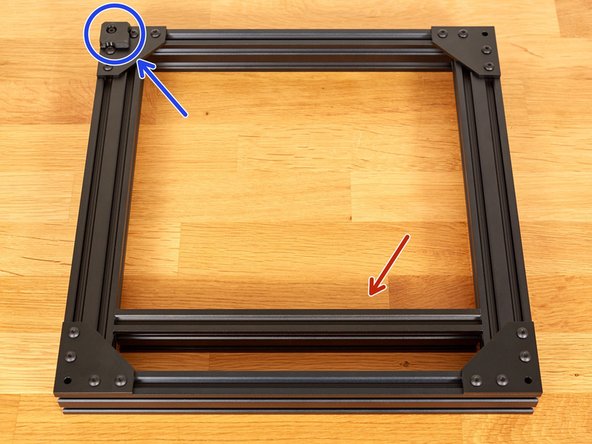

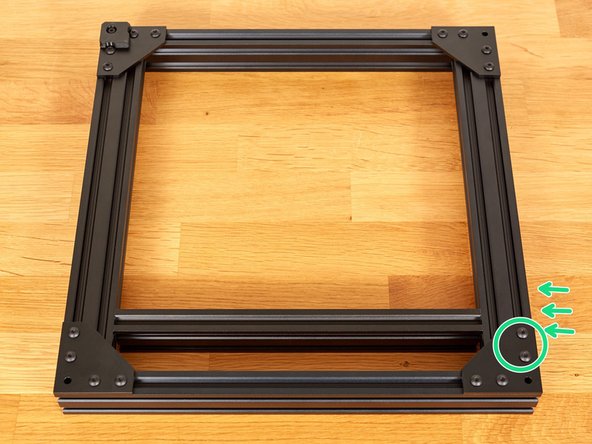

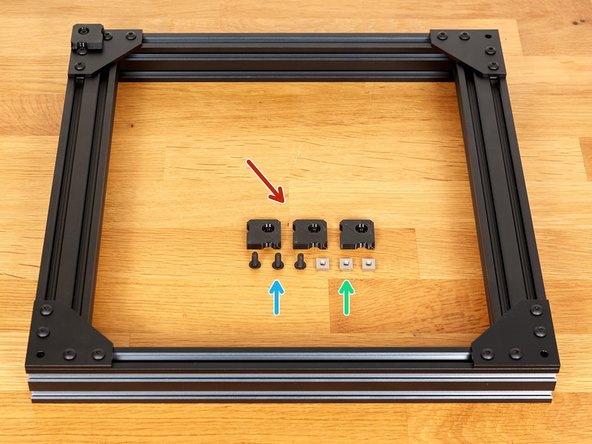

Prepare 12x t-nuts and test them individually with an M5 screw. This is a little tip to avoid having to redo all the hard work of squaring the frame if a t-nut is defective. You can thanks 3DMN for this handy tip :)

-

Inserts 3x t-nuts on each side (12x in total) as seen on the 2nd and 3rd picture.

-

-

-

Take 4x t-nuts and slide them as seen on the 1st picture.

-

With 4x M5x10, assemble the second 370mm extrusion + plate assembly you have prepared in the beginning of this chapter.

-

Do not tighten them fully yet!

-

-

-

Take your time with this step. Ask the help of someone else if you feel the need of having a third hand (please don't use one of your foot).

-

Move the assembly in vertical position with the 3D printed foot on the bottom left.

-

Make sure you are on a flat and plane surface.

-

Apply pressure in the directions shown and tighten strongly the 2x M5x10 screws.

-

-

-

Take your time with this step. It is the last squaring operation for the base of the frame.

-

Move down the assembly with and position the 3D printed foot on the left and back.

-

Carefully insert the 290mm extrusion in between as shown in the 1st image.

-

Be gentle with the 290mm extrusion or you might mark permanently the assembled extrusions.

-

Apply pressure as shown in the image and tighten the M5 screw strongly.

-

-

-

Verify that all the 6 latest M5x10 screws bolted are fully tightened (max 4.5Nm).

-

Prepare the following parts:

-

3x 3D printed feet (foot.stl)

-

3x M5x12 screws

-

3x t-nuts

-