-

-

If you haven't check the Z axis parts during the preflight check then you should do it now or you might have problem during this chapter.

-

Note that in this chapter you will see images of MK3(S) Y carriage but all steps are exactly the same for MK2(S) and MK2.5(S).

-

-

-

Make sure you have removed the original lead screw covers as specified in the preflight check and disassembly guide

-

This is not optional, the original lead screw covers are not compatible with the Bear Z motor mounts.

-

Screw the Bear z_leadscrew_caps on both motors.

-

The z_leadscrew_caps should screw down to the Z motor but should not be tight at all. Make sure the lead screw can turn freely.

-

-

-

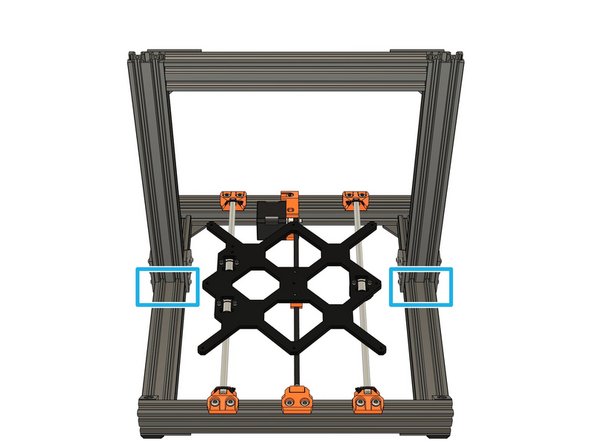

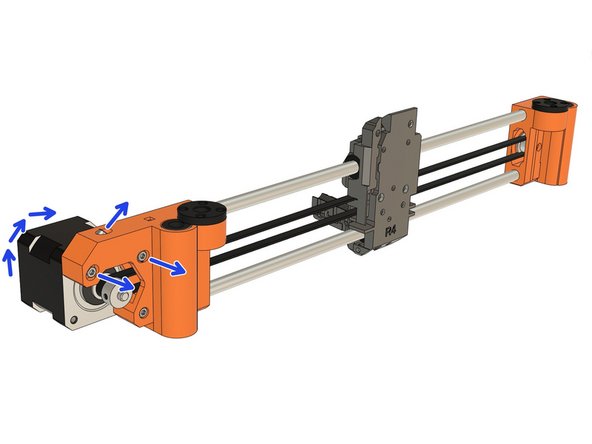

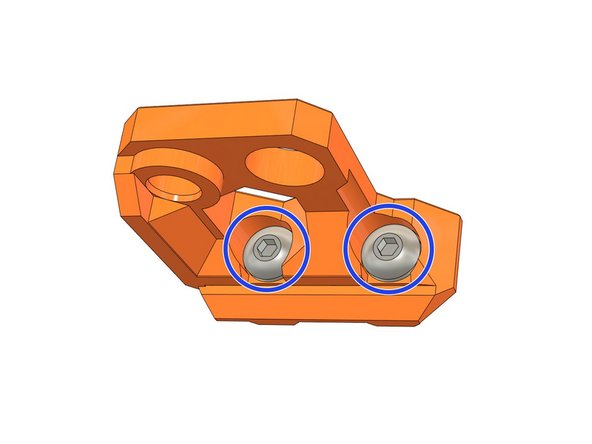

Insert 2x M5x10 screws in the z_motor_mount.

-

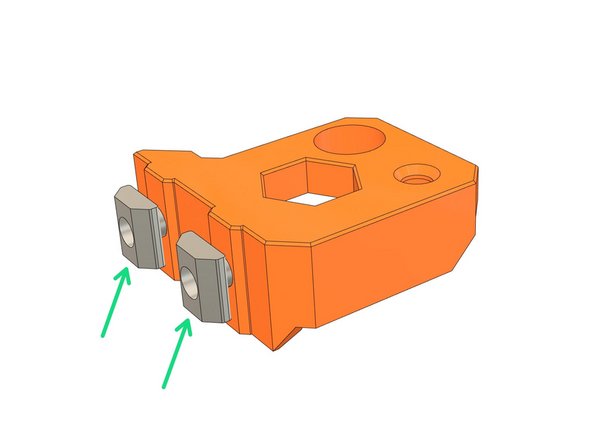

Engage 2x t-nuts on the M5 screws (1-2 turns) and place them vertically.

-

Repeat with the remaining z_motor_mount.

-

-

-

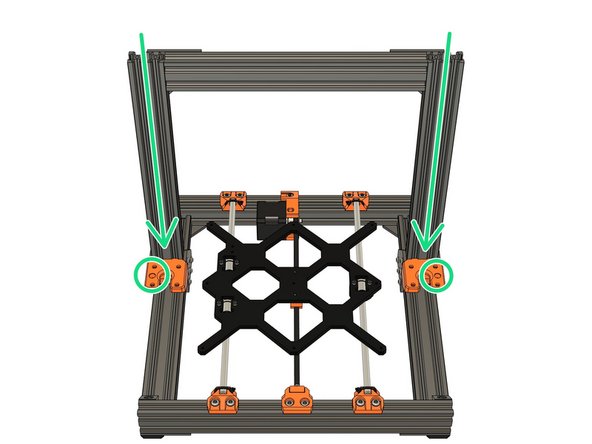

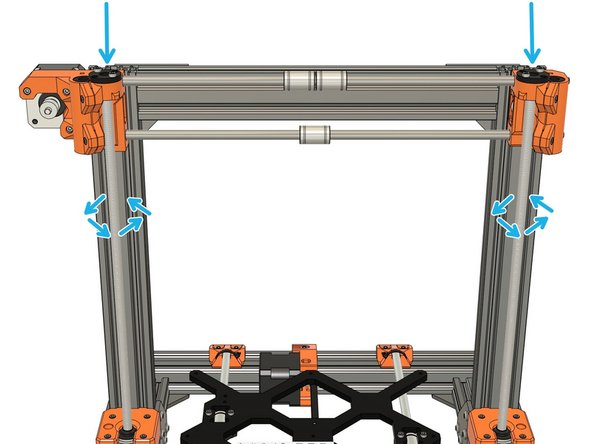

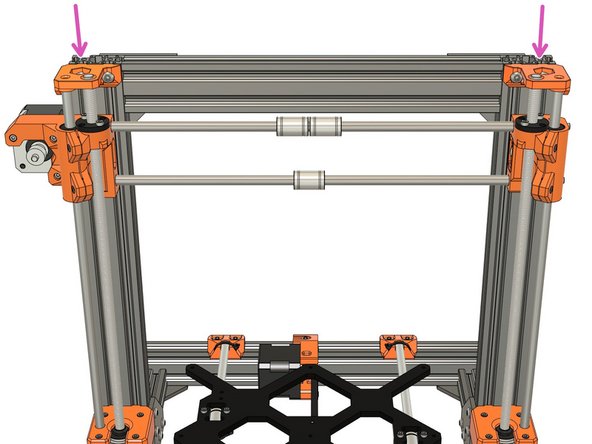

Make sure this section is clean of dust, it will be used as reference for the z_motor_mounts.

-

Slide the z_motor_mount from the top of the frame. Note the orientation, the hole for the Z smooth rods should face outside the frame

-

Double check the orientation of your z_motor_mount or it will make the next steps impossible.

-

-

-

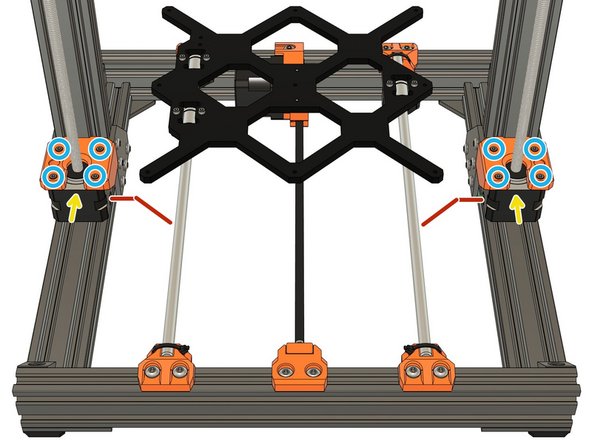

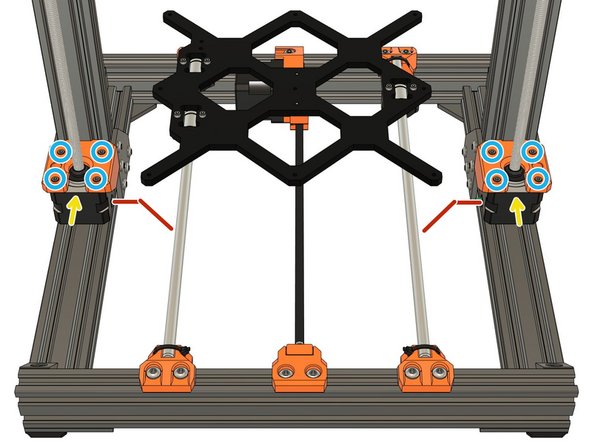

Slide the Z motors in the z_motor_mounts. The motor cable should be oriented inside the frame (red lines on the images).

-

Secure the Z motors in place with 8x M3x10 screws (reused from your original Prusa). Press the motor in the direction of the yellow arrows while tightening incrementally the screws.

-

Note that the previous z_motor_mounts of Bear 2.0 was using M3x12 screws and they will be too long for these new mounts.

-

Check the orientation of your motor cables.

-

-

-

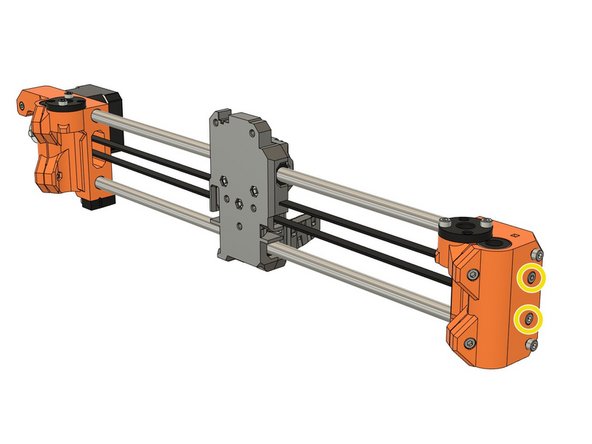

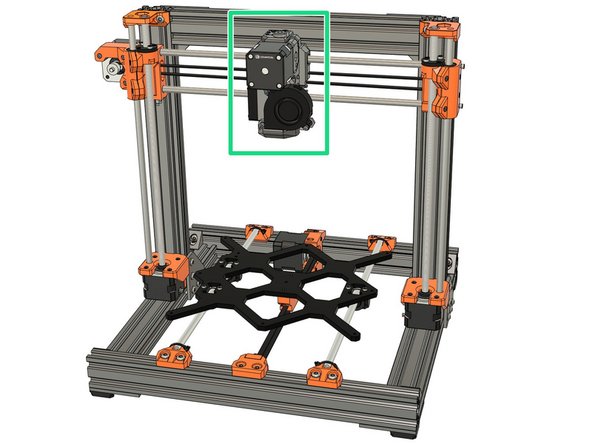

In this step we prepare the X axis to later assemble it on the Z axis.

-

If you are using the Bear X axis or Original Prusa MK2(S)/MK2.5(S) X axis you need to unscrew a little the smooth rods screws (approx. 2mm).

-

If you still have the X carriage (or extruder) in place you must release the belt tension in X axis.

-

Bear extruder and X axis (BearExxa), BearMera of Bear X axis with Bondtech extruder: release tension using the belt tensioning screws.

-

Original Prusa MK3(S): remove the 2x top motor screws and release tension of the screw on top of the arm. Then rotate the X motor.

-

Original Prusa MK2(S) or MK2.5(S): remove the 2x top motor screws and rotate the X motor.

-

Be careful, if you still have the X carriage (or the extruder) in place you will have to disassemble the Z motors to insert the X axis in the next step.

-

-

-

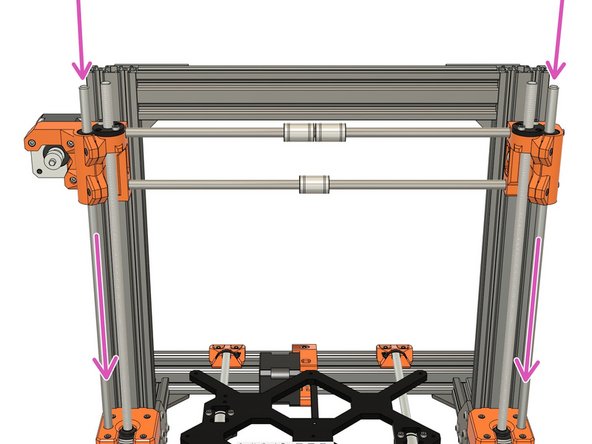

Be careful with this step as you might damage the lead screw nuts (black nuts on the X ends).

-

Place the X axis on top of the Z lead screws. Carefully rotate by hand the Z lead screw to engage and move down the X axis.

-

Be very careful, never force on the lead screw nuts or you might damage them.

-

Rotate the lead screws in synchronization.

-

Continue to rotate the Z lead screws simultaneously until you can align the top X smooth rod with the bottom of top Z axis extrusion.

-

Verify the X axis is parallel and make correction if necessary.

-

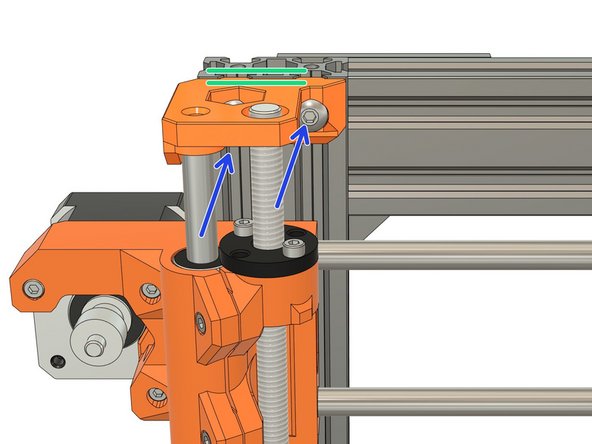

Very gently slide the two Z smooth rods (320mm long) down to the Z motors. The smooth rods must be fully inserted until they touch the Z motors (you can hear a "metallic click" when you reach the motor).

-

Verify the Z smooth rods are fully inserted down to the Z motors. This is very important as it might affect the alignment of your X axis later.

-

-

-

Insert 2x M5x10 screws in one of the z_top.

-

Engage 2x t-nuts on the M5 screws (1-2 turns) and place them vertically.

-

Repeat with the remaining z_top.

-

-

-

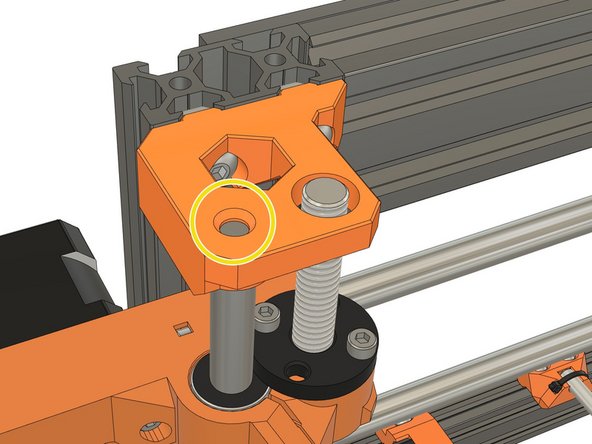

Install the z_tops on top of the Z axis. T-nuts must go into the extrusion's grooves and the smooth rods in the smallest of the two front holes.

-

You must press down the z_tops until the smooth rod is touching on top of the hole.

-

This is very important as it might affect the alignment of your X axis later.

-

Make sure the z_tops are parallel to the top of the extrusion

-

Tighten the 2x M5x10 screws.

-

Double check that the smooth rods are fully inserted in the z_tops.

-

-

-

In this chapter you will have to follow external guides. As the Bear frame supports different extruders and X axis it would make this guide too long and hard to follow. Thank you for your comprehension :)

-

Reinstalll the extruder on the X axis by following the external guide(S) according to your extruder and X axis:

-

BearExxa (Bear extruder and X axis): start with 3. Extruder, then 4. Extruder and X axis assembly up to step 10 and finish with 5. Final adjustments and calibration up step 8.

-

BearMera (E3D Hemera): start with 3. BearMera extruder up to step 14, and then 4. Adjustments.

-

Bondtech on Bear X axis: follow our guide here.

-

Original Prusa extruders installation guides: MK3S, MK2.5S, MK3 (spiral wrap), MK3 (textile sleeve), MK2.5 (spiral wrap), MK2.5 (textile sleeve), MK2S.

-

Bondtech extruder on original Prusa X axis: choose the guide corresonding to your extruder on support.bondtech.se/c/Prusa.

-

-

-

Congratulations you have finished this chapter :-)

-

Go to the next chapter: [invalid guide link].

-