-

-

Ensure the hotend has cooled down and turn off the printer.

-

Remove the steel sheet and place a sheet of paper on your heated bed. Remove any residual filament from the nozzle.

-

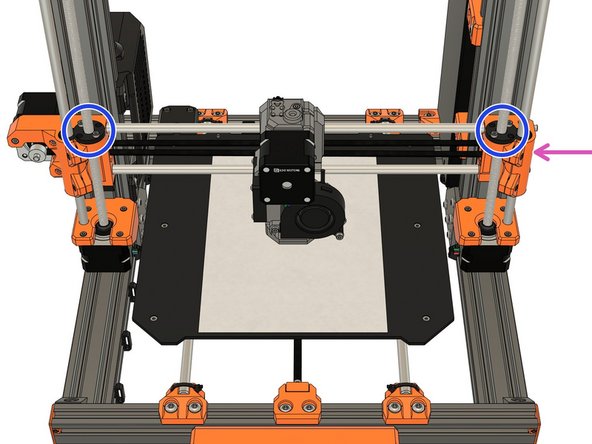

Center your extruder on the X axis. Move it down by rotating both the Z lead screws at the same time. Move the extruder down until the nozzle is just touching the paper.

-

Make sure the X axis is flat. You can move the extruder left and right and compare the distance with the heated bed.

-

Stop when the nozzle is just touching the paper.

-

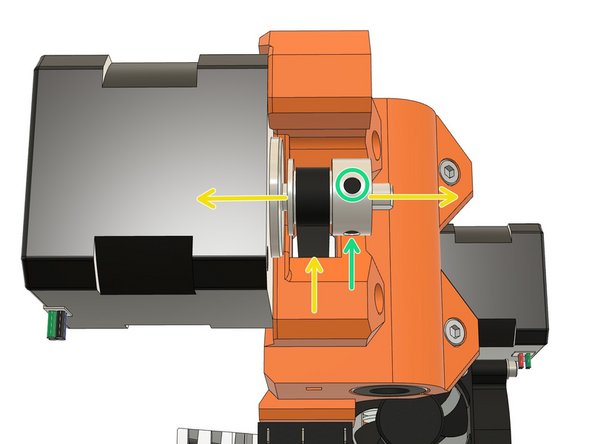

Place the middle section of a zip tie under the Pinda.

-

Loosen the M3x10 screw and gently move the PINDA down until it is touching the zip tie.

-

Tighten the M3x10 screw to secure the PINDA in place.

-

-

-

Plugin and turn on the printer.

-

Using the screen menu, move the X axis up until it crashes in to the Z tops. The stepper motors will skip, making a noise - this will not damage the motors.

-

If your printer can't reach the Z tops, unplug the printer and plug it back. You can now reach Z tops.

-

Using the screen menu, move the X axis down until the nozzle is approximately 10-15mm from the heated bed.

-

-

-

Turn off the printer and center the extruder.

-

If you have applied tension to the belt, unscrew the belt tensioner on x_end_idler until the belt is relaxed.

-

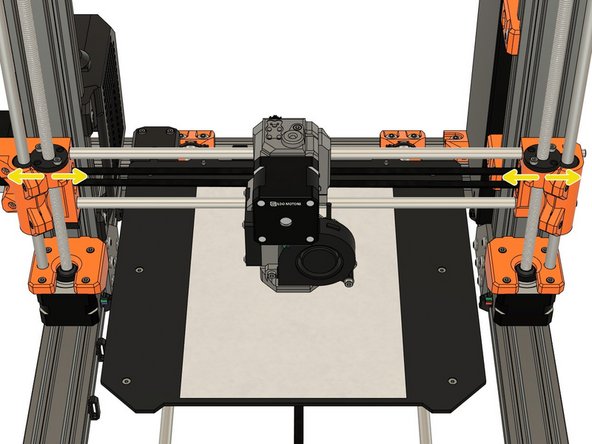

Loosen the screws which secure the trapezoidal nuts. This is to ensure that the Trapezoidal nuts 'self-centre' on the lead screws.

-

Make sure the trapezoidal nuts are moving freely.

-

Alternate between all 4 screws evenly while tightening (alternate between both sides during the process). Don't apply any lateral force on the trapezoidal nuts.

-

-

-

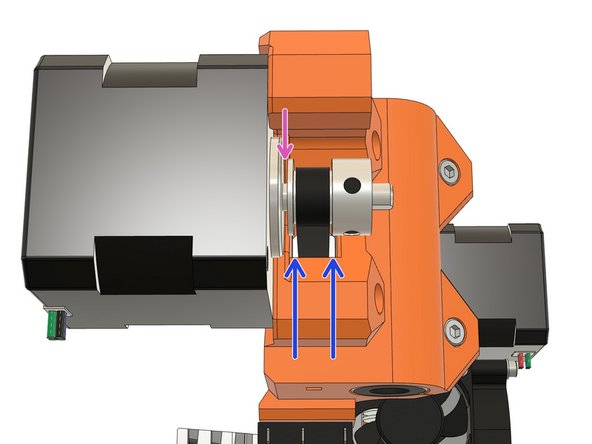

Loosen both pulley set screws a little.

-

Align the pulley with the belt hole of the x_end_motor.

-

Tighten the set screws alternately.

-

Verify that the belt is not touching the x_end_motor.

-

Verify that the drive pulley is not touching the X motor.

-

-

-

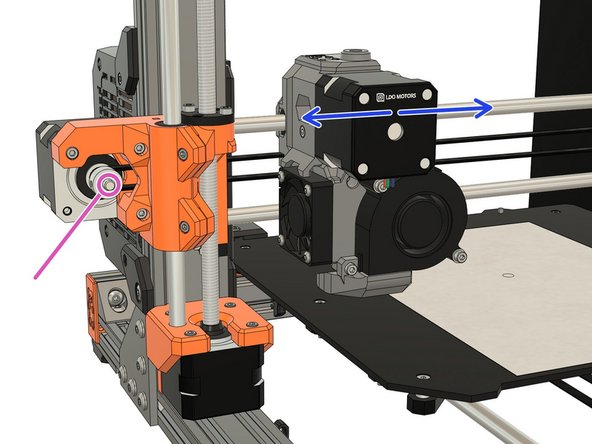

Grip the X motor shaft with pliers to prevent it moving (grab the flat side of the shaft).

-

Tension the belt, by tightening the screws in the x_end_idler. Do this while trying to move the extruder to the left or right. The belt should stay straight and should not bow up and skip over the drive pulley teeth.

-

No need to be very precise with the belt tension here as the final tension will be improved later.

-

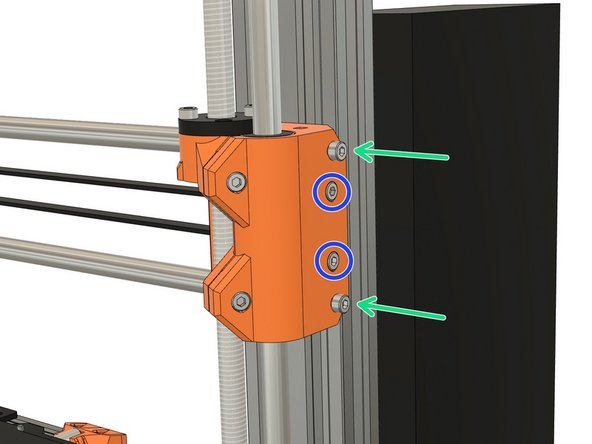

Thread two M3x10 screws inside the top and bottom holes of x_end_idler. Do not screw them fully, leave a gap of 1-2mm as shown on the third image.

There is a problem with this step “Thread two M3x10 screws inside the top and bottom holes of x_end_idler “

there is no nut inside to hold the screw so the screw will never push the x smooth rods as asked in the next step

Catalin Costel Lates - Resolved on Release Reply

The screw are self threading into the plastic. This will be more than strong enough to hold the screws and push the rod. It also avoid the screw to get unscrewed due to vibrations.

-

-

-

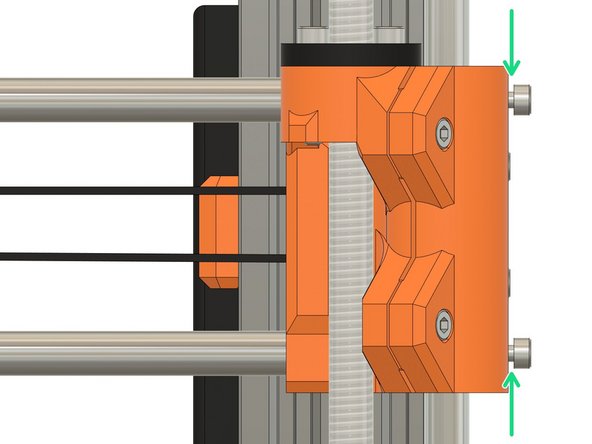

Not all X axis have the exact same length because of tolerances (including on Original Prusa printers). This step will adjust your X axis length.

-

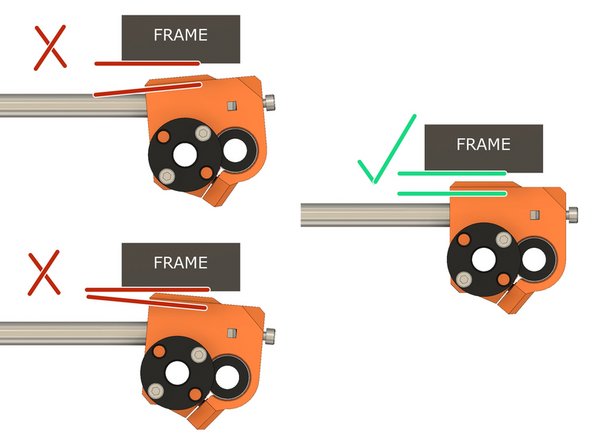

The 1st image shows what happens to the X ends when you tension the X axis belt. We want to have the X ends as parallel as possible to the frame (or it will affect the X belt motion).

-

1st image, top left: when the X axis is too short.

-

1st image, bottom left: when X axis is too long.

-

1st image, right: when the X axis has the perfect length.

-

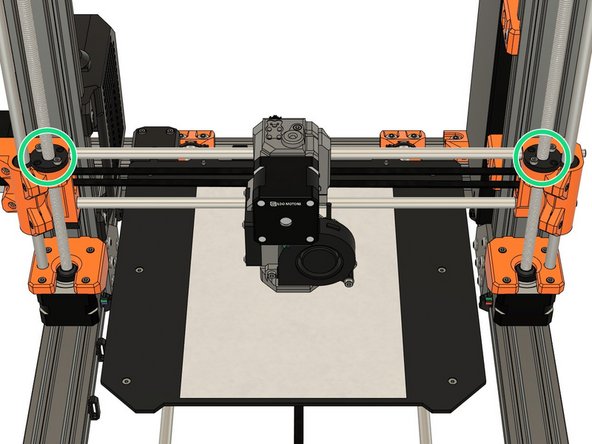

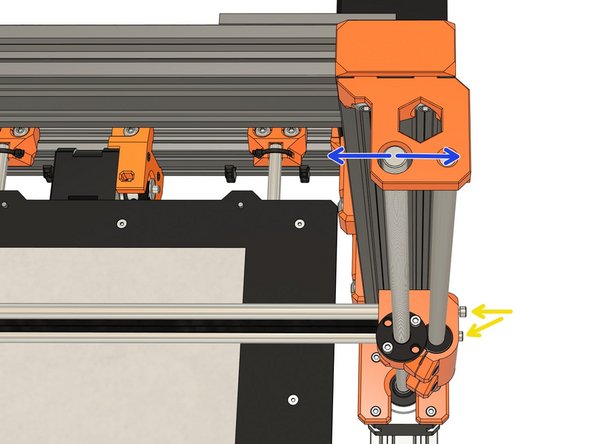

To adjust the length of the X axis we need to use the two M3x10 screws of the x_en_idler and look at the Z tops.

-

While you tighten the M3x10 screws keep an eye on the Z tops. The M3x10 screws will move the Z leadscrews laterally (left or right), adjust them to have the Z leadscrews as possible centered.

-

Note that the M3x10 screws will not move back and forth the Z lead screw position, only laterally.

-

-

-

To set perfect belt tension we will make it vibrate and tune it to a certain frequency, just like a guitar. To do that we will use a smartphone application.

-

Download and install the Pano Tuner application (developed by Kaleloft LLC) on your smartphone.

-

-

-

Turn off the printer (if your hotend is higher than 50°C, let the hotend cool down first until the hotend fan stops spinning)

-

Launch the Pano Tuner app and place your smartphone on the heated bed. Make sure there is no noise in the room that could disrupt the measurement (like a ceiling fan).

-

-

-

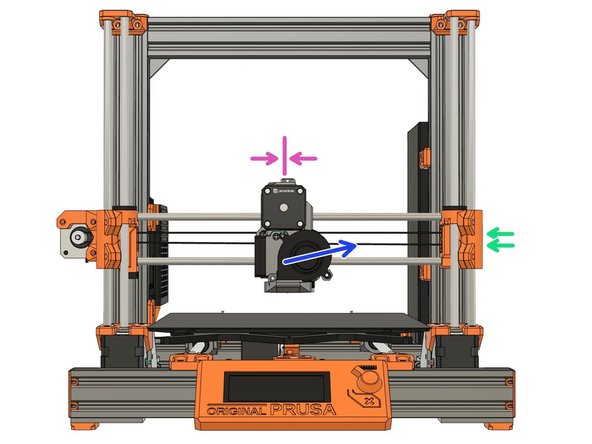

Move the extruder to the middle of the X axis.

-

Pluck the lower belt to make it vibrate. Don't pluck it too much as it might touch the carriage and produce a wrong frequency.

-

Adjust the belt tension until you have a value around 90Hz. Between each adjustment, move the extruder to all the way to the left and right and then center it again.

-

It is very important to move left and right the extruder between each measurement to relax some tension in the belt.

-

If your belt is new, you can repeat this procedure after a few prints. A new belt will loosen in the first hours of use.

-

-

-

For improved reliability and print quality, the Bear extruder is slightly taller than the original MK2.5S/MK3S extruder. We provide customized firmware to pass Selftest and (XY)Z Calibration for the taller size of the Bear extruder. Our firmware also provides a faster and safer rotation for hotend fan (if using something different than Noctua).

-

After the self test, you can go back to Prusa firmware if you prefer. However, you will have to use the stock hotend fan (Noctua).

-

Select and download the latest Bear calibration firmware here: github.com/bear-lab-3d/Prusa-Firmware/re...:

-

MK3S Einsy-Rambo 10a firmware name: Bear_Cal_FW***_MK3S-EINSy10a.hex

-

MK2.5S Mini-Rambo 13a firmware name: Bear_Cal_FW***_MK25S-RAMBo13a.zip

-

MK2.5S Mini-Rambo 10a firmware name: Bear_Cal_FW***_MK25S-RAMBo10a.zip

-

MK2.5S firmware comes as a ZIP file containing several languages of the firmware. They all contain English. Extract the ZIP file and choose the language you prefer to use (in addition to English).

-

If you don't know which Mini-Rambo board you have, please refer to this document

-

-

-

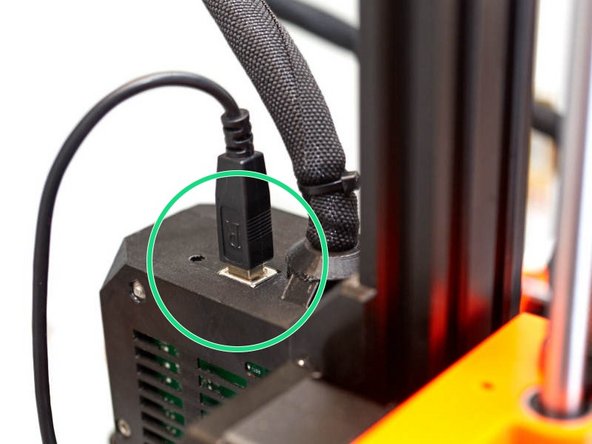

Get a USB A to B cable.

-

Connect the USB cable to the Mini-Rambo / Einsy-Rambo.

-

Connect the other side of the USB cable to a computer that is running PrusaSlicer.

-

We recommend to you use PrusaSlicer to flash the firmware.

-

Turn on the printer.

-

-

-

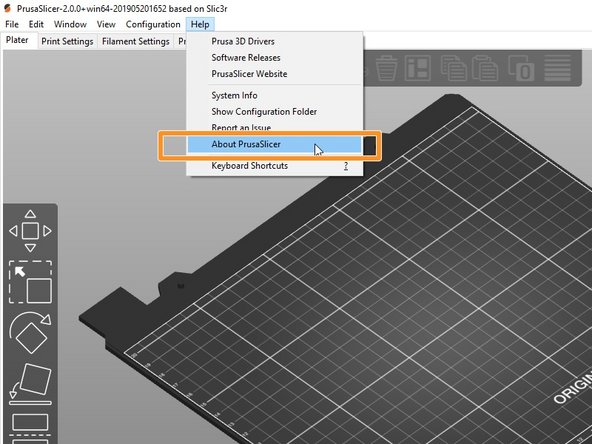

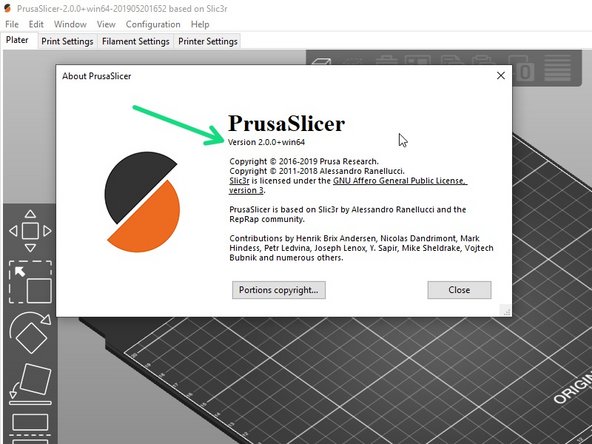

Start PrusaSlicer and go to the top menu Help -> About ...

-

Verify that the slicer version is equal or greater than 2.0.0.

-

If the version is equal or greater: go to the next step

-

If your version is lower: download and install the version shown above from this page: prusa3d.com/prusaslicer.

-

You can update to the most recent version, however, we may not have tested with that version.

-

-

-

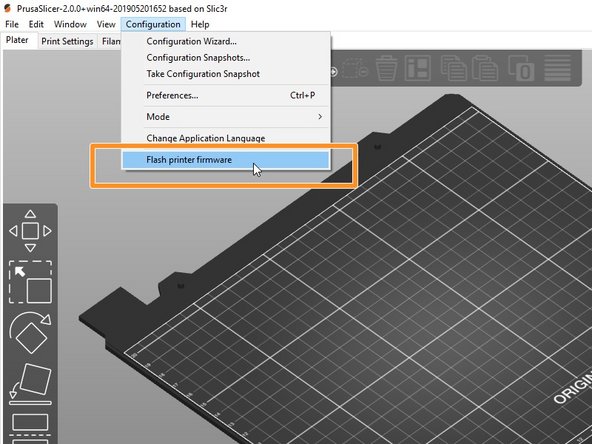

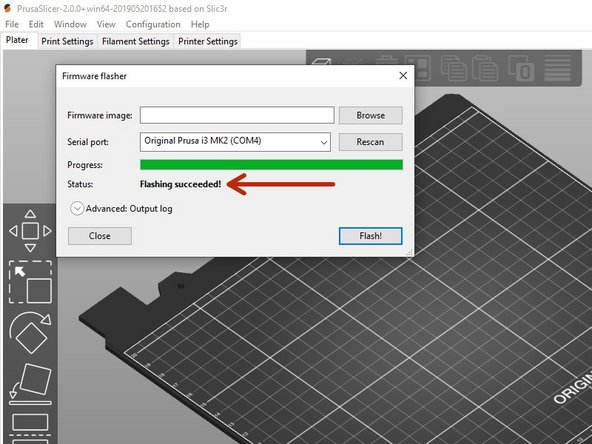

Verify that the printer is turned on.

-

Start PrusaSlicer and navigate to the top menu Configuration -> Flash printer firmware

-

Select the appropriate Bear calibration firmware *.hex file using the Browse button.

-

Verify that the printer is detected in the "Serial port:" window. If not, check that the USB cable is firmly connected to both the printer and the computer. select "Rescan"

-

Click the button Flash! to flash the Bear calibration firmware.

-

Never turn off the printer or disconnect the USB cable while flashing the firmware!

-

Wait until you get a Flashing succeeded! message.

-

In case of issues while flashing the firmware read the Prusa troubleshooting article.

-

-

-

Turn the printer off and and then on.

-

Run the "Selftest" in calibration settings.

-

If errors occur during selftest, please fix them before going further.

-

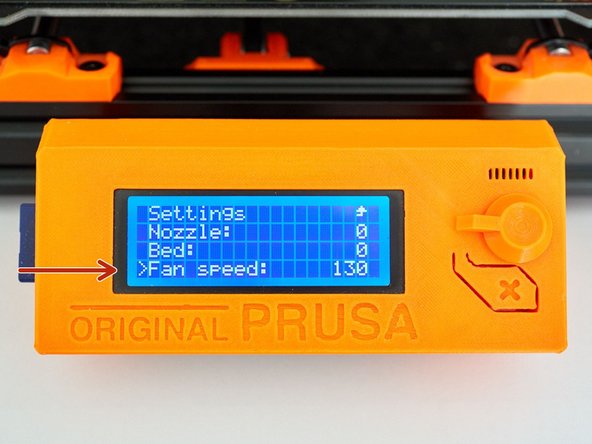

In Settings -> Temperature -> Fan speed set the value at 130 if you print lots of PETG and 255 if you print lots of PLA. For other materials select a value suitable for your most used filament.

-

Run PID calibration in calibration settings.

-

Choose a temperature that matches your most used printing temperature.

I seem to be stuck at this part. I keep getting an error during the first step of the Self Test process, as the unorthodox Hotend fan wiring is giving an error which I can’t seem to get past. Another issue is the X carriage always fails when attempting First Layer Calibration and crashes into the right side of z axis which then prompts a Z leveling enforced message or something to that effect.

If anyone could offer some advice on how to complete these final steps successfully… much appreciated!

t.

-

-

-

Heat up the nozzle by selecting Settings -> Temperature -> Nozzle: and insert PLA filament.

-

Make sure you have the steel sheet on the printer.

-

Run the Z Calibration.

-

Because the extrusion multiplier and filament diameter are not calibrated yet, it will only give a first approximation of the first layer height.

-

-

-

Follow our "Extrusion multiplier" guide here: 8. Extrusion multiplier and filament diameter

-

-

-

Congratulations, you have finished to install and calibrate your Bear extruder.

-

Happy printing :)

-

Cancel: I did not complete this guide.

17 other people completed this guide.

9 Comments

Very good instructions. Really like the original. There is just one thing that is still unclear to me. If I use the Bear x axes and the Bear extruder, can I then install the original Prusa firmware after the self-test?

Happy you like the instructions. Yes you can go back to Prusa firmware or continue to use our firmware, as you prefer. If you go back to Prusa firmware and you are not using the Noctua hotend fan, then make sure to set Altfan to OFF in the experimental menu as explained in this page: https://help.prusa3d.com/article/experim...

Hey, is it a good idea to just use the X-parts (motor,idler,idler tensioner) and not the upgraded extruder parts? I like the printed parts of the X axis and don’t really want to mess with the extruder.

Tom Brychnac - Resolved on Release Reply

I thought that might be the case after looking at it... I guess I will be printing the extruder parts some time soon then. That raises another question, is PETG sufficient for the extruder parts with the exception of the fan shroud, or is it a lot better to print with ASA? Thank you for the answer :).

Unfortunately the Bear X axis isn’t compatible with the stock extruder (the belt path is different)

Yeah, really great project with outstanding guide and all the supplement info! Thanks for your work!

Fantastic project! And a good assembly guide, easy to follow indeed. I spotted one small mistake in Step 16: refers to the Bear calibration firmware *.hex file , this should read stock Prusa firmware *.hex file. In the text under the blue dot is another such reference.

J. van der Wulp - Resolved on Release Reply