-

-

If you didn't check the Z axis parts during the preflight check then you should do it now or you may have problems during this chapter.

-

Note that in this chapter, images will only show the MK3(S) Y carriage, but that all steps are exactly the same for the MK2(S) and MK2.5(S).

-

-

-

Make sure you have removed the original lead screw covers as specified in the preflight check and disassembly guide

-

This is not optional, the original lead screw covers are not compatible with the Bear Z motor mounts.

-

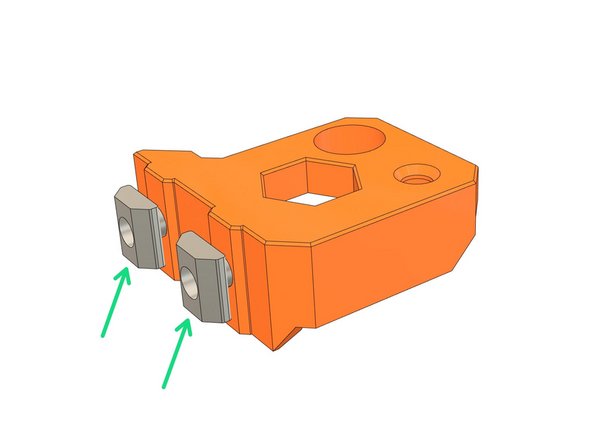

Screw the Bear z_leadscrew_caps on both motors.

-

The z_leadscrew_caps should screw down to the Z motor but should not be tight at all. Make sure the lead screw can turn freely.

-

-

-

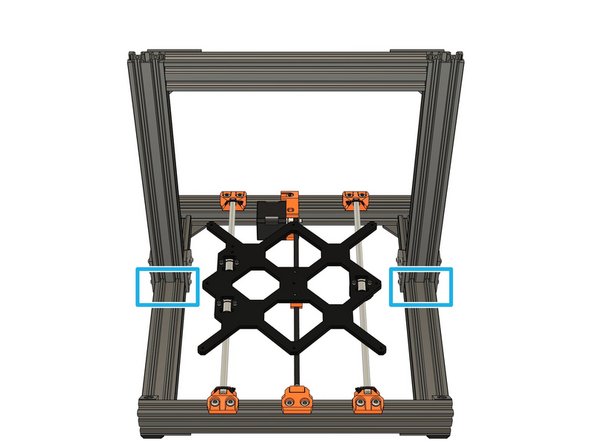

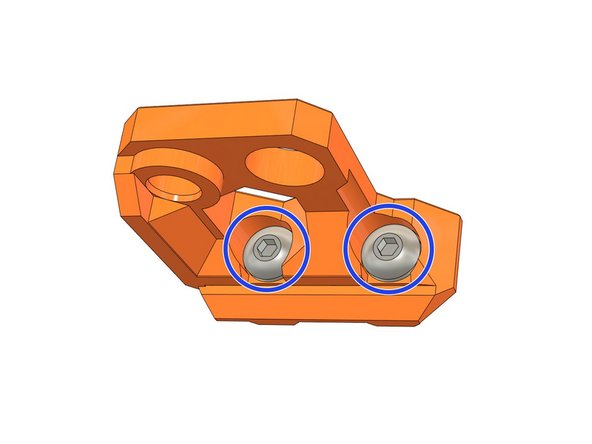

Insert 2x M5x10 screws in the z_motor_mount.

-

Thread 2x t-nuts on the M5 screws (1-2 turns) and place them vertically.

-

Repeat with the remaining z_motor_mount.

-

-

-

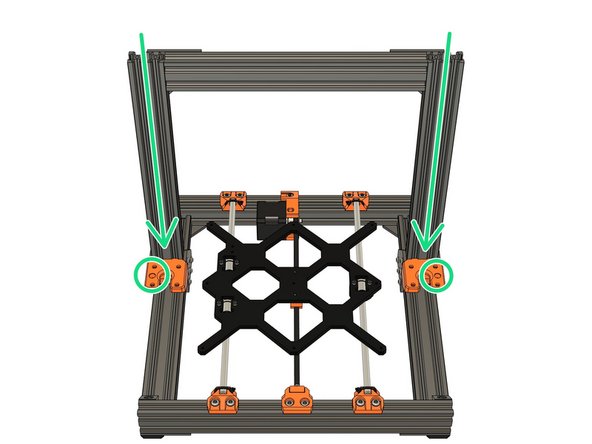

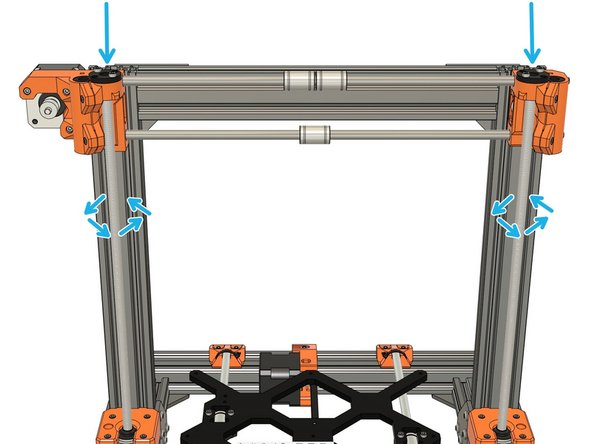

Make sure this section is clean of dust, it will be used as reference for the z_motor_mounts.

-

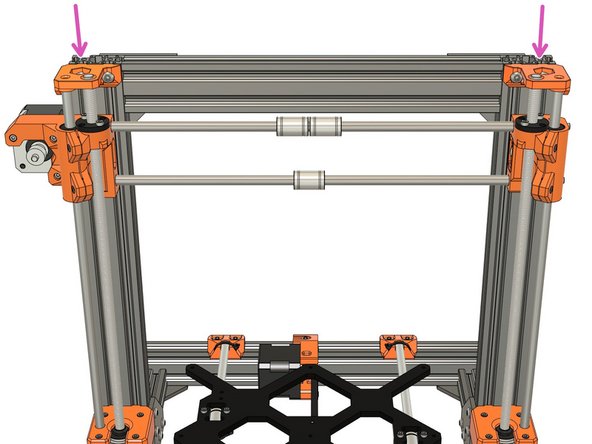

Slide the z_motor_mount from the top of the frame, slotting the t-nuts into the extrusion channels. Note the orientation, the hole for the Z smooth rods should be to the outside the frame

-

Tighten the M5x10 strongly.

-

Double check the orientation of your z_motor_mount or it will make the next steps impossible.

-

-

-

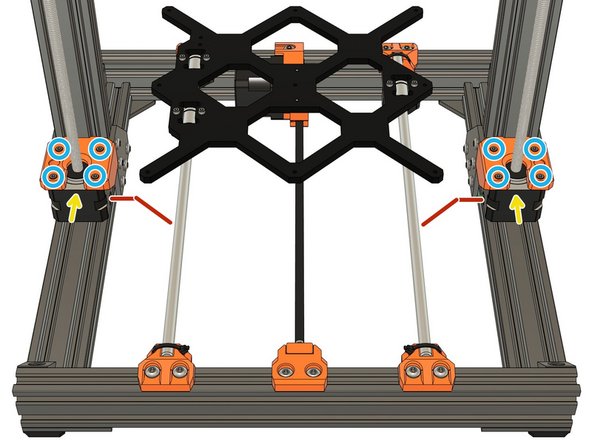

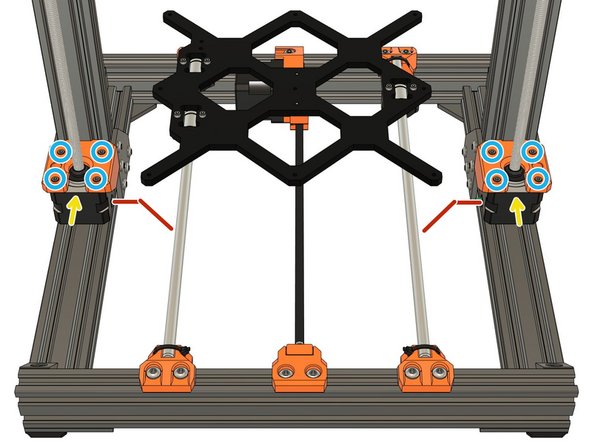

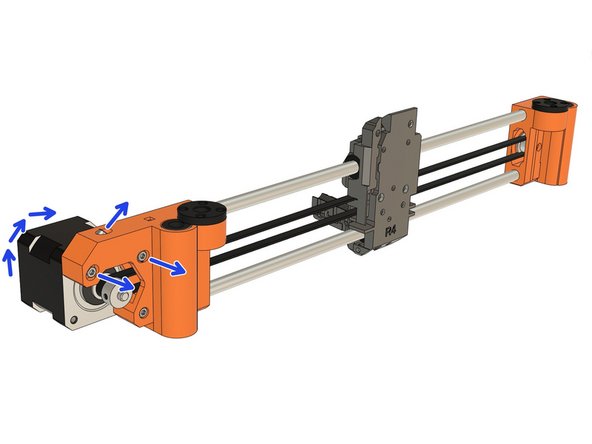

Slide the Z motors in the z_motor_mounts. The motor cable should be oriented towards the inside of the frame (red lines on the images).

-

The Z motors have different cable length. The motor with shorter cables must go on the side of the dual Y axis bearing (left on the images).

-

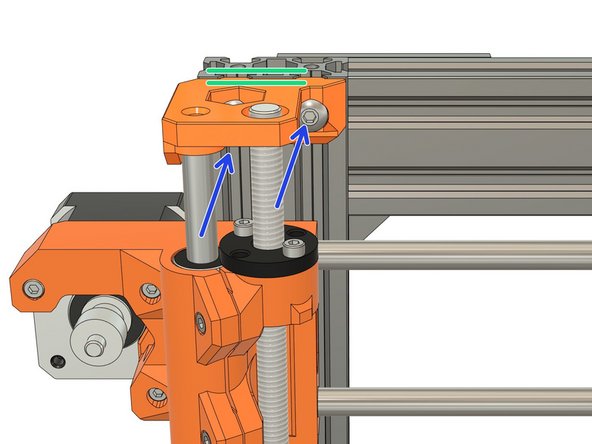

Secure the Z motors in place with 8x M3x10 screws (reused from your original Prusa). Press the motor in the direction of the yellow arrows while tightening the screws evenly, incrementally and in turn.

-

Note that the previous, Bear 2.0 ''z_motor_mounts',' used M3x12 screws and they will be too long for these new mounts.

-

Previous version of Bear or Original Prusa are using washer on the M3x10. This is not useful anymore, you can discard them.

-

Check the orientation of your motor cables.

-

-

-

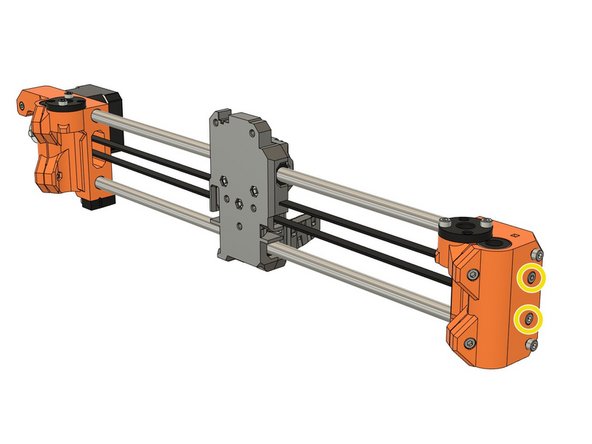

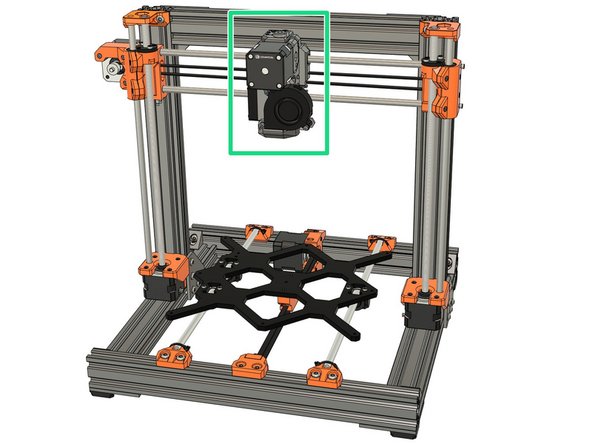

In this step we prepare the X axis for later assembly on the Z axis.

-

If you are using the Bear X axis or the Original Prusa MK2(S)/MK2.5(S) X axis, you will need to unscrew the smooth rod tensioning screws, as shown (by approx. 2mm).

-

If you still have the X carriage (or extruder) in place, you must ensure that the X axis belt is not under tension.

-

Bear extruder and X axis (BearExxa), BearMera of Bear X axis with Bondtech extruder: release tension using the belt tensioning screws.

-

Original Prusa MK3(S): remove the 2x top motor screws and release tension of the screw on top of the arm. Then rotate the X motor.

-

Original Prusa MK2(S) or MK2.5(S): remove the 2x top motor screws and rotate the X motor.

-

Be careful, if you still have the X carriage (or the extruder) in place you will have to disassemble the Z motors to insert the X axis in the next step.

-

-

-

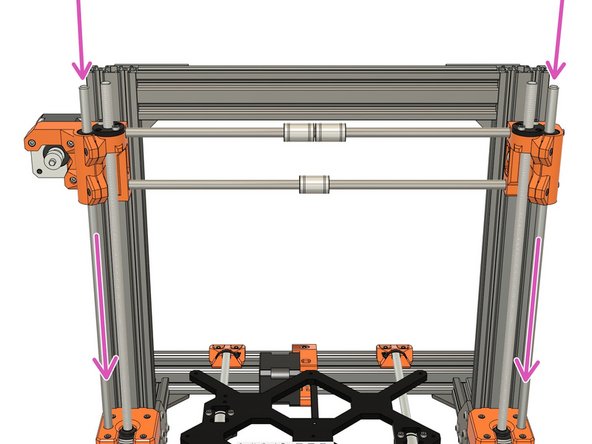

Be careful and take your time with this step to not damage the Z lead screw nuts and bearings.

-

Place the X axis on top of the Z lead screws. Carefully rotate, by hand, both Z lead screws to engage with the nuts and move down the X axis.

-

Never apply force on the lead screw nuts or you might damage them.

-

Rotate both lead screws, simultaneously, keeping the X axis level as it moves down the Z axis.

-

Continue to rotate both Z lead screws until you can align the top X smooth rod with the bottom of top Z axis extrusion.

-

Check that the X axis is parallel and rotate one or other of the lead screws until it is.

-

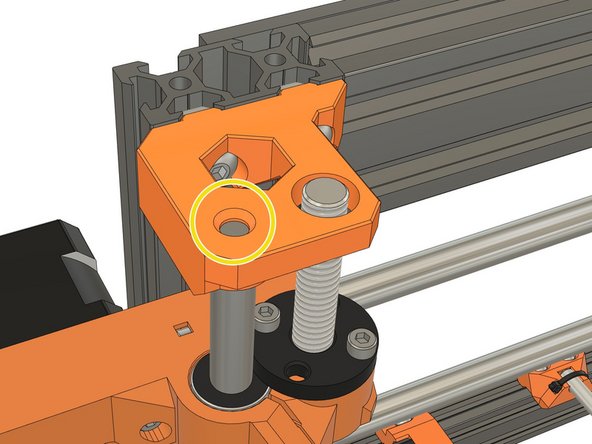

Very gently, insert the two Z smooth rods (320mm long) into the bearings and down to the Z motors. The smooth rods must be fully inserted. They must touch the Z motor body itself (you can hear a "metallic click" when you reach the motor).

-

Verify the Z smooth rods are fully inserted into the Z motor mount and actually touch the Z motors. This is very important as it might affect the alignment of your X axis later.

-

-

-

Insert 2x M5x10 screws in one of the z_top.

-

Thread 2x t-nuts on the M5 screws (1-2 turns) and place them vertically.

-

Repeat with the remaining z_top.

-

-

-

Install the z_tops on top of the Z axis. T-nuts must go into the extrusion's grooves and the smooth rods in the smallest of the two front holes.

-

You must press down the z_tops until the smooth rod is touching the top of the hole.

-

This is very important as it might affect the alignment of your X axis later.

-

Make sure the z_tops are parallel to the top of the extrusion

-

Tighten the 2x M5x10 screws.

-

Double check that the smooth rods are fully inserted in the z_tops.

-

-

-

To install the extruder you have to follow external guides. As the Bear frame supports different extruders and X axes it would make this guide too long and complicated to follow. Thank you for your understanding :)

-

Reinstall the extruder on the X axis by following the external guide(s) relevant to the extruder and X axis of your choice:

-

BearExxa (Bear extruder and X axis): start with 3. Extruder, then 4. Extruder and X axis assembly up to step 10 and finish with 5. Final adjustments and calibration up step 8.

-

BearMera (E3D Hemera): start with 3. BearMera extruder up to step 14, and then 4. Adjustments.

-

Bondtech on Bear X axis: follow our guide here.

-

Original Prusa extruders installation guides: MK3S+, MK3S, MK2.5S, MK3 (spiral wrap), MK3 (textile sleeve), MK2.5 (spiral wrap), MK2.5 (textile sleeve), MK2S.

-

Bondtech extruder on original Prusa X axis: choose the guide corresonding to your extruder on support.bondtech.se/c/Prusa.

-

-

-

Congratulations you have finished this chapter :)

-

Go to the next chapter: 07. Heated bed.

-

Cancel: I did not complete this guide.

25 other people completed this guide.