-

-

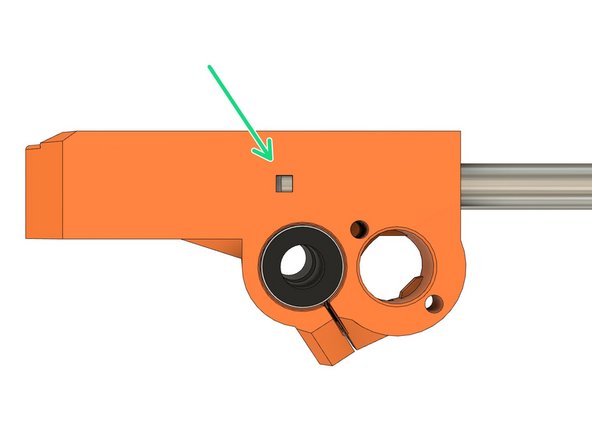

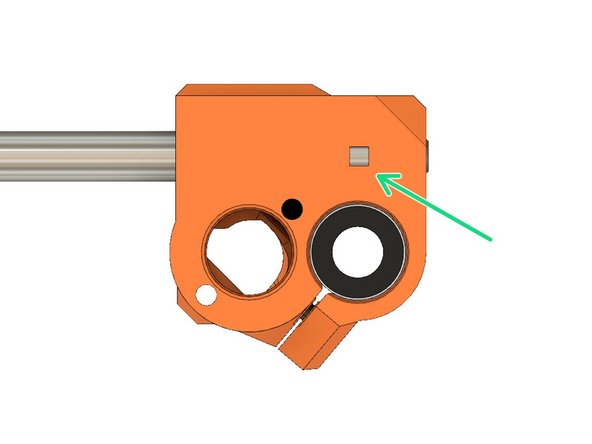

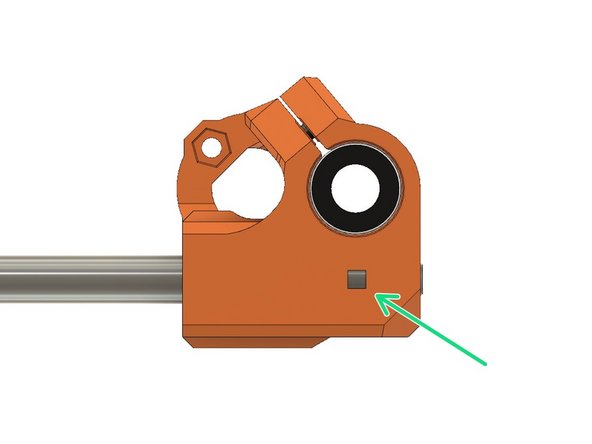

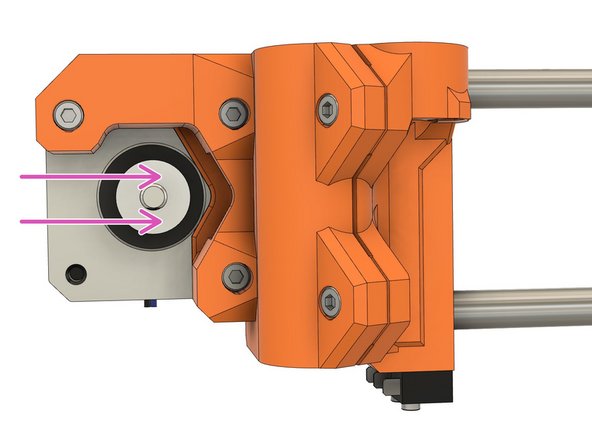

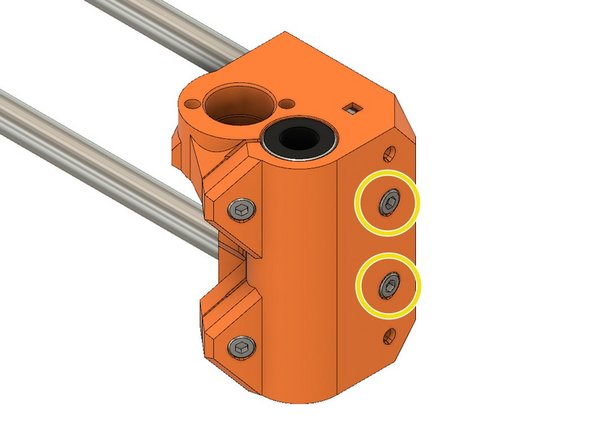

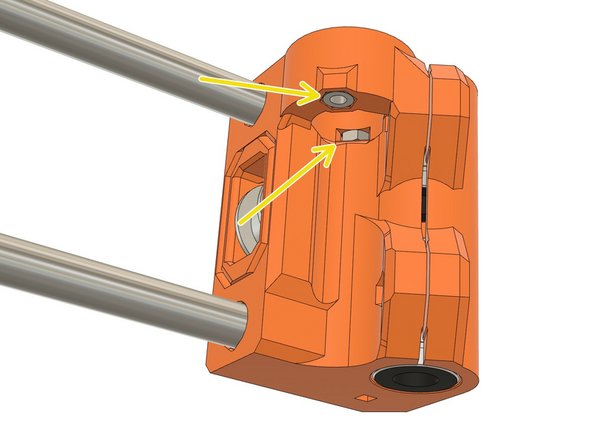

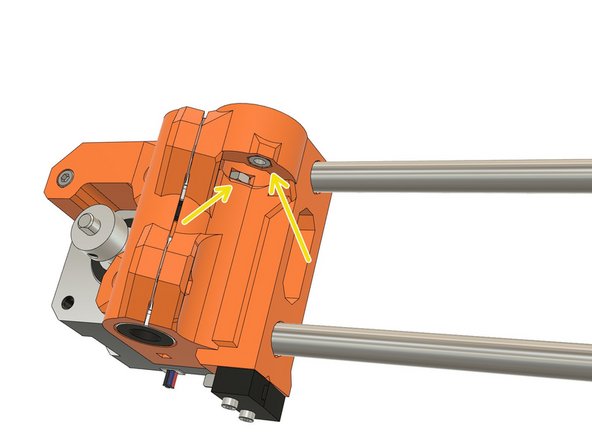

Insert a M3x18mm socket head screw in one of the x_end_idler clamp holes. This screw helps insert the hex nut.

-

Using tweezers, hold a M3 hex nut so that it can be threaded onto the M3x18mm socket head screw. Tighten that screw until the M3 hex nut is firmly seated.

-

Remove the M3x18 socket head screw and repeat on the other clamp hole.

-

-

-

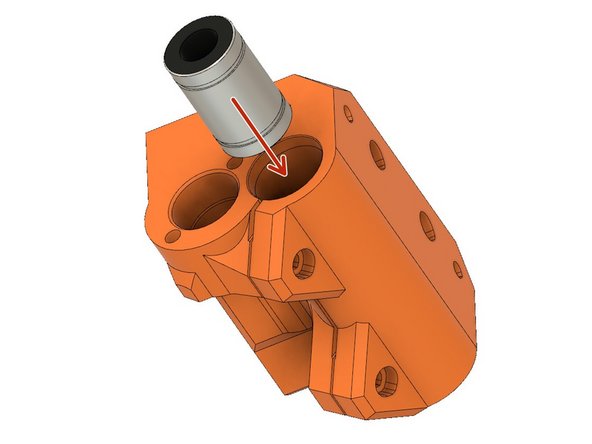

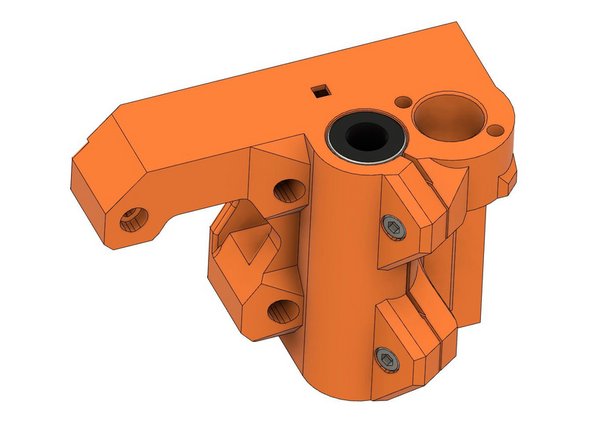

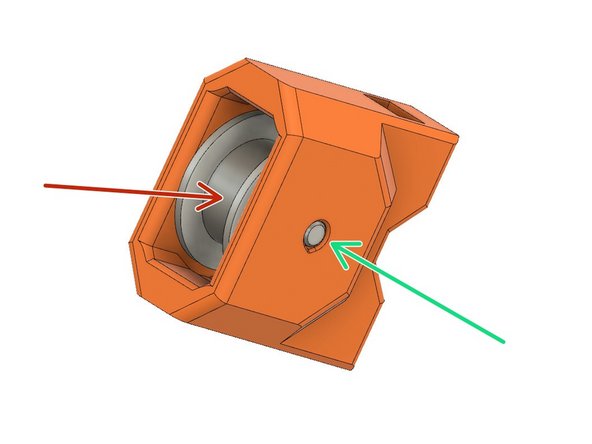

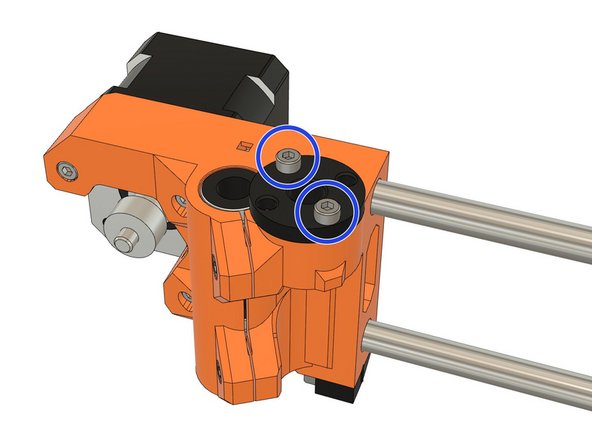

Insert an LM8UU linear bearing into the x_end_idler until it hits the internal stop.

-

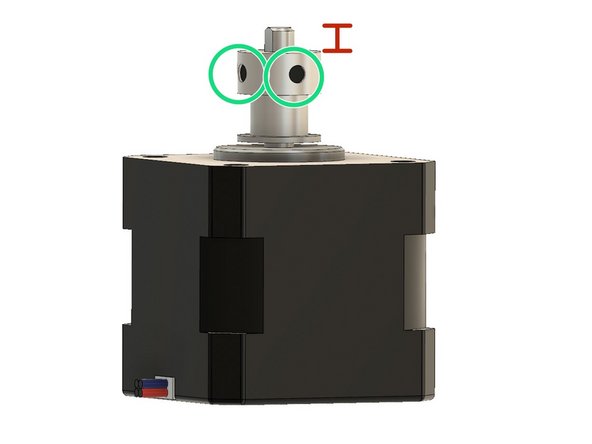

The next LM8UU linear bearing will have to be inserted so that the rows of ball bearings are at 45° to the rows in the other bearing.

-

Insert that LM8UU linear bearing into the x_end_idler until it hits the internal stop.

-

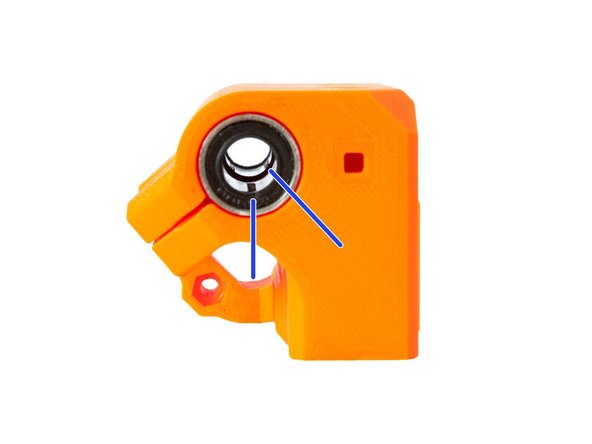

Verify that the rows of balls are rotated at an angle of 45° from each other (as shown in the photograph).

-

-

-

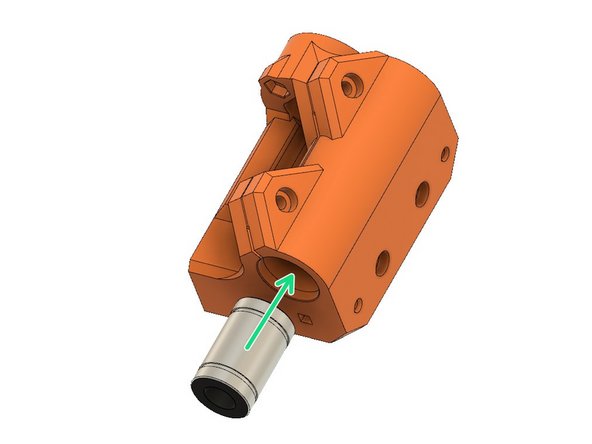

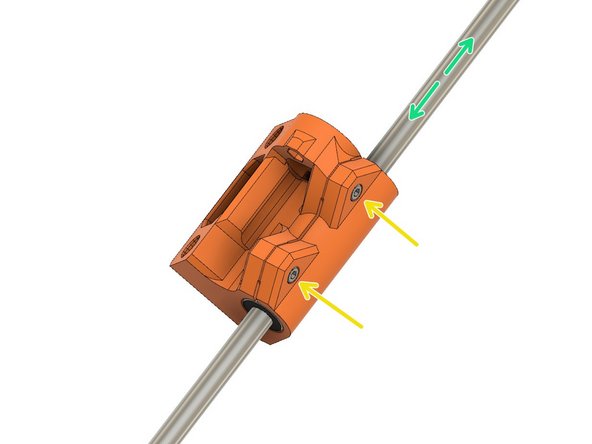

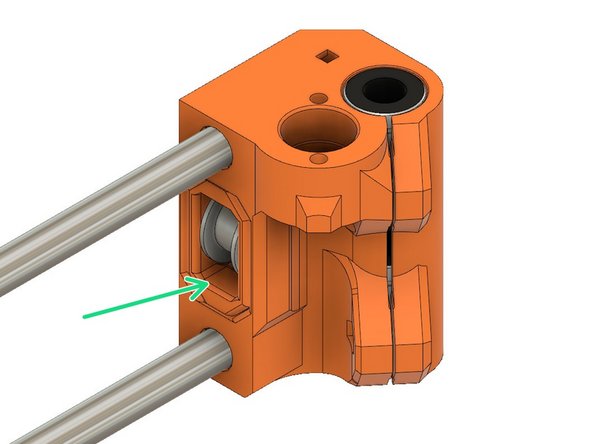

Temporarily insert a 8mm smooth rod through both LM8UU linear bearings.

-

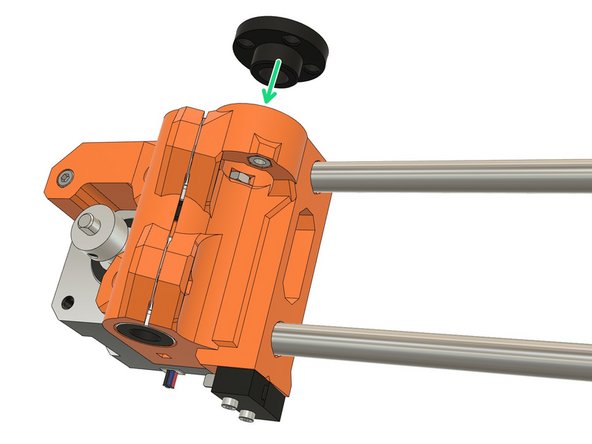

Engage two M3x10 socket head screws in the hex nuts, but do not tighten them at this time.

-

Alternately tighten the two M3x10 clamp screws to secure the linear bearings. Slide the smooth rods back and forth while tightening.

-

Don't over-tighten the clamp screws; they need to be just tight enough to keep the bearings from moving.

-

Remove the 8mm smooth rod.

-

-

-

Repeat the 3 previous steps on the x_end_motor

-

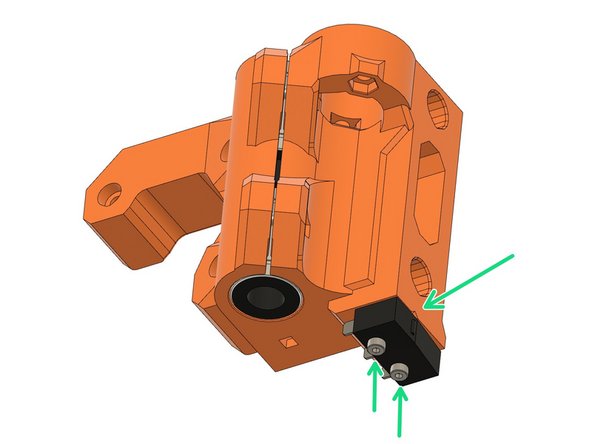

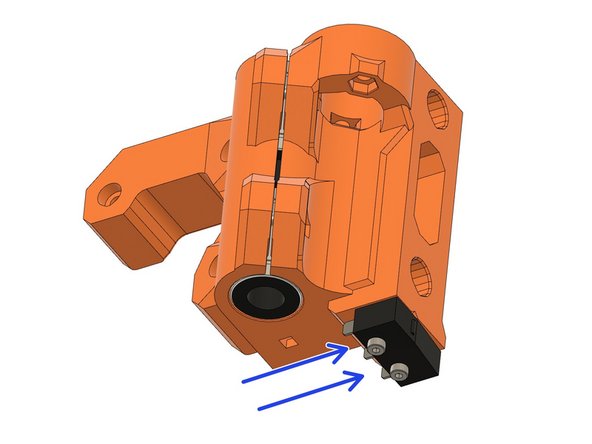

MK2(S) or MK2.5(S) only: Use two M2x12 screws to attach the x-endstop switch. Ensure the correct orientation of the switch. The microswitch should be oriented so that it is closest to the v-notch in the printed part.

-

MK2(S) or MK2.5(S) only: While tightening the screws, apply gentle pressure in the direction shown.

-

MK2(S) or MK2.5(S) only: Do not over-tighten the M2x12 screws!

-

MK2(S) or MK2.5(S) only: Double check the orientation of the endstop.

-

-

-

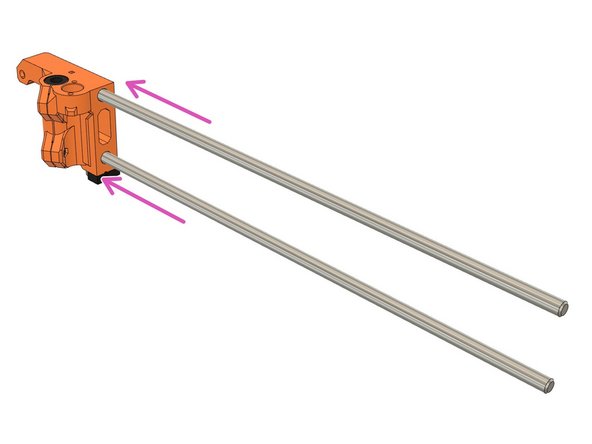

Check the holes for the smooth rods in the x_end_motor part and ensure that they are clean and free from obstructions.

-

Slide the two 370mm smooth rods in the x_end_motor.

-

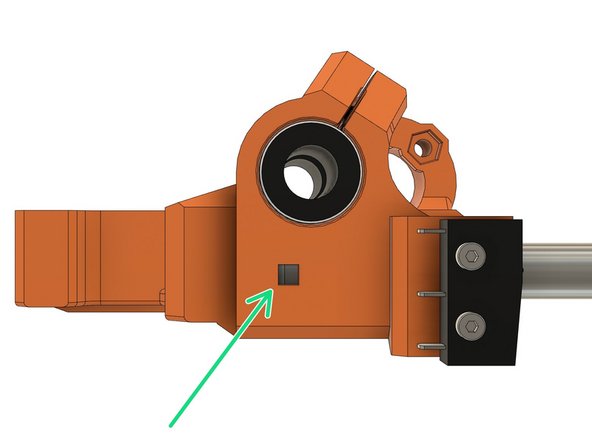

Ensure that the smooth rods are fully inserted. You can check in the little windows on top and bottom.

-

If it is too hard to insert the smooth rods you can use a quality metal drill of 8mm and hand drill the first centimeter. Warning: don't drill the hole up to the end, only the first centimeter.

-

-

-

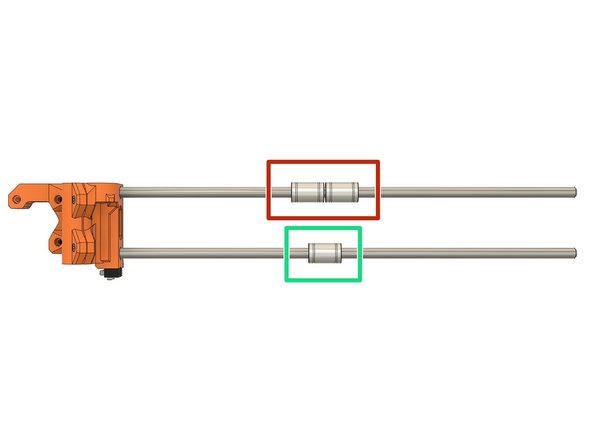

Insert two LM8UU linear bearings on the top smooth rod.

-

Insert one LM8UU linear bearing on the bottom smooth rod.

-

Be very careful inserting the LM8UU linear bearings.

-

-

-

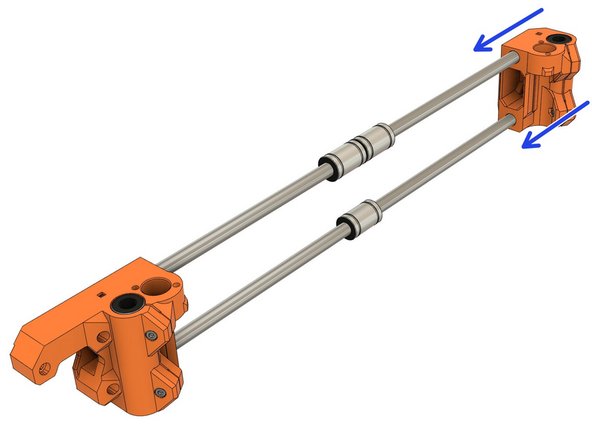

Insert both rods simultaneously into the x_end_idler and provide even pressure to force the rods all the way in.

-

Ensure that the smooth rods are fully inserted by checking the little windows on top and bottom.

-

Take the time to double check observation windows on both x_end_idler and x_end_motor.

-

If it is too hard to insert the smooth rods you can use a quality metal drill of 8mm and hand drill the first centimeter. Warning: don't drill the hole up to the end, only the first centimeter.

-

-

-

The 2GT 16T pulley's teeth are not visible on the images.

-

Position the 2GT 16T pulley so that approximately 3.5 to 4 mm of the motor shaft protrudes. Ensure the pulley is not touching the motor.

-

Align one of the set screws on the flat side of the motor shaft and then tighten both set screws alternately until they are snug.

-

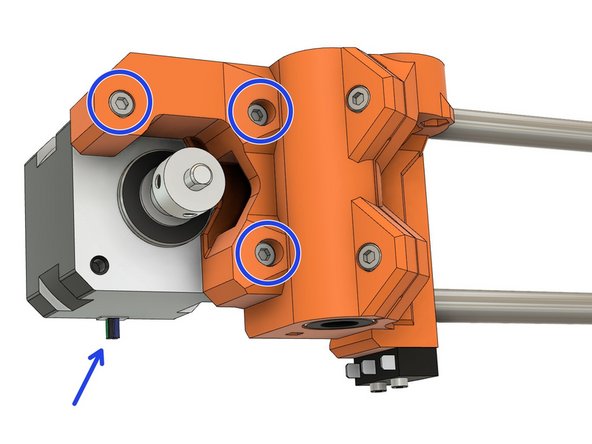

Attach the x-axis motor with three M3x18 screws. Don't tighten them fully yet. Note the orientation of the wires.

-

Finish to tighten the M3x18 screws while applying gentle pressure in the direction shown

-

Double check the pulley position and ensure it does not touch the motor.

-

-

-

Insert the idler in the x_end_idler_tensioner.

-

Press the dowel pin through the x_end_idler_tensioner and idler bearings.

-

Verify that the dowel pin is not protruding from either side.

-

Verify that the idler spins freely.

-

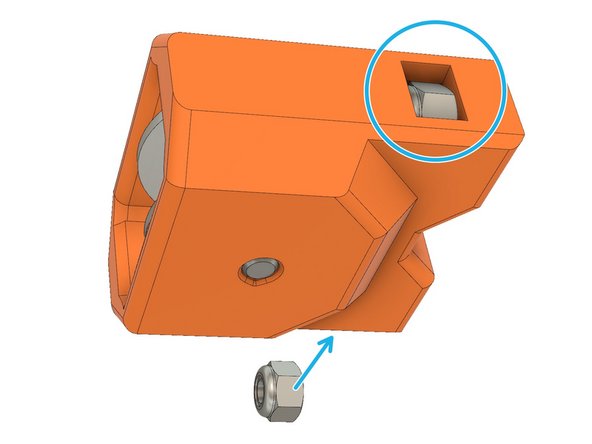

Insert two M3 nylock nuts in the top and bottom of the x_end_idler_tensioner. Note the orientation of the nylock nuts.

-

-

-

Insert the x_end_idler_tensioner in the x_end_idler.

-

Secure it with two M3x18 screws. Don't tighten the screws, only engage them.

-

-

-

Insert two M3 hex nuts in the dedicated pockets of the x_end_idler.

-

Note the orientation of the trapezoidal nut.

-

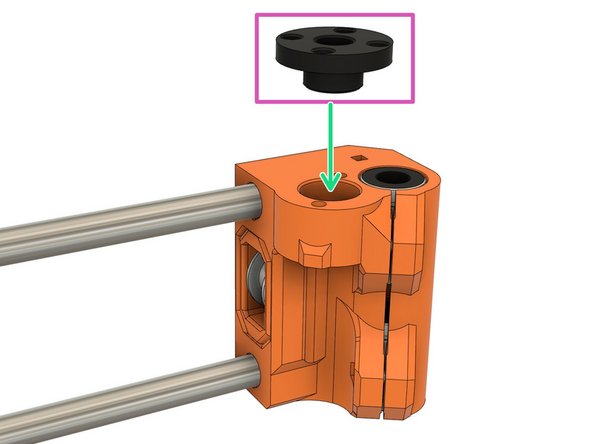

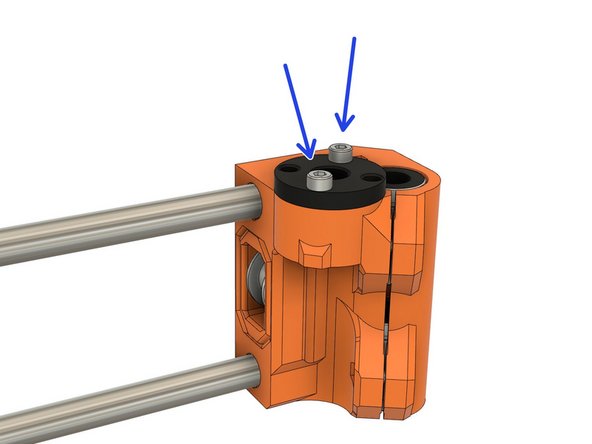

Insert a trapezoidal nut in the top of the x_end_idler.

-

Use two M3x18 screws, to tighten the trapezoidal nut in place. Do not over-tighten the screws.

-

Verify the orientation of the trapezoidal nut.

-

-

-

Insert two M3 hex nuts into the dedicated pockets of the x_end_motor.

-

Insert a trapezoidal nut in the top of the x_end_motor.

-

Use two M3x18 screws, to tighten the trapezoidal nut in place. Do not over-tighten the screws.

-

Verify the orientation of the trapezoidal nut.

-

-

-

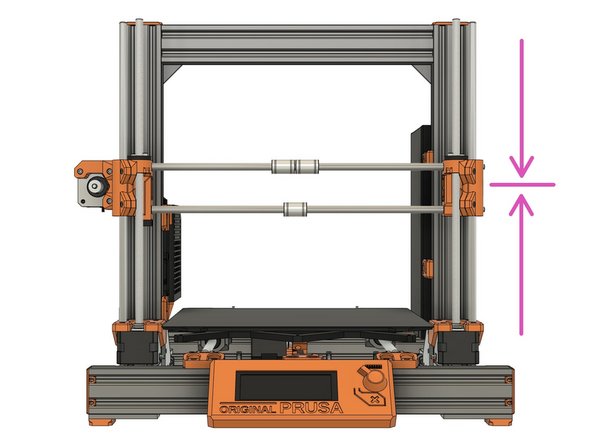

These steps are using the Bear Upgrade frame 2.1 as example but can be applied to Original Prusa frames and previous Bear Upgrade frame versions.

-

Bear Upgrade frame only: Remove the z_end_caps.

-

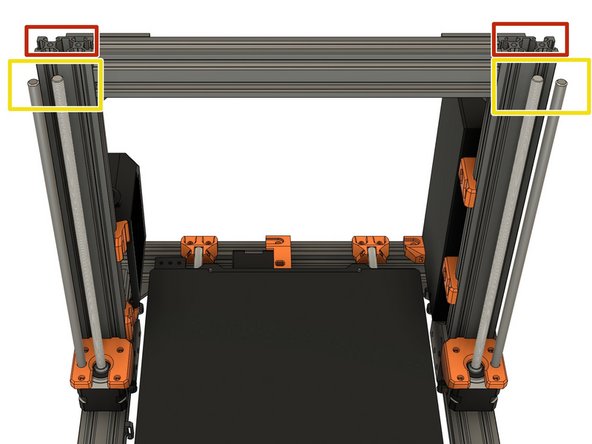

Remove the z_tops that hold the Z smooth rods.

-

Carefully slide the X axis assembly on the Z-axis. Rotate both lead screws to engage the X axis with the trapezoidal nuts.

-

Continue to rotate both lead screws by hand, to move the X axis assembly down a few centimetres. If the X rods are not parallel with the top of the Z axis, rotate a lead screw on one side only, until the X axis assembly is parallel to the top of the Z axis.

-

Continue to move the X axis assembly downwards until you reach the middle of the Z axis. Keep the X axis as level as possible.

-

-

-

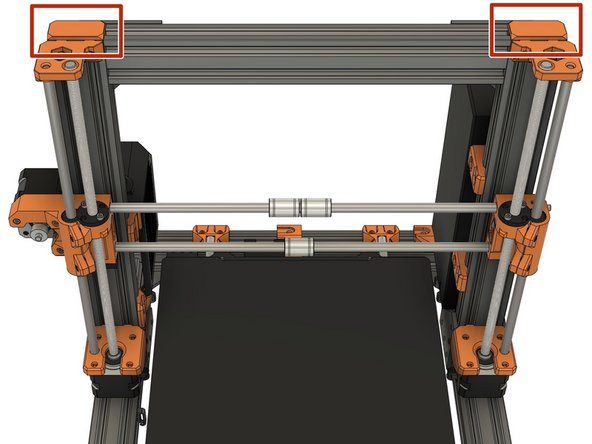

These steps are using the Bear Upgrade frame 2.1 as example but can be applied to Original Prusa frames and previous Bear Upgrade frame versions.

-

Install the Z axis tops and tighten them.

-

Bear Upgrade frame only: Make sure the z_tops are flush with the Z smooth rods on both sides

-

Bear Upgrade frame only: Tighten the z_ends_caps back in place.

-

-

-

Congratulations you have finished this chapter :-)

-

Go to the next chapter: 3. Extruder

-

Cancel: I did not complete this guide.

24 other people completed this guide.