-

-

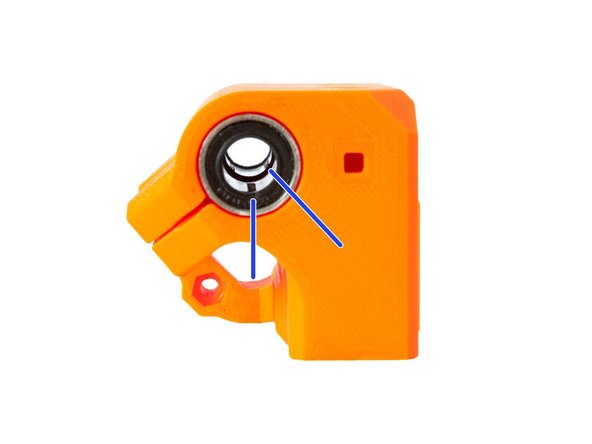

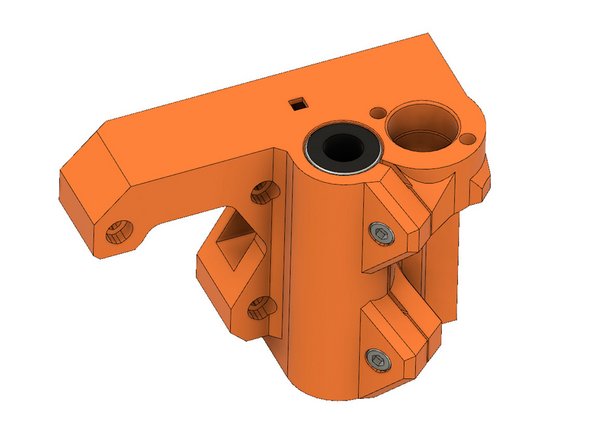

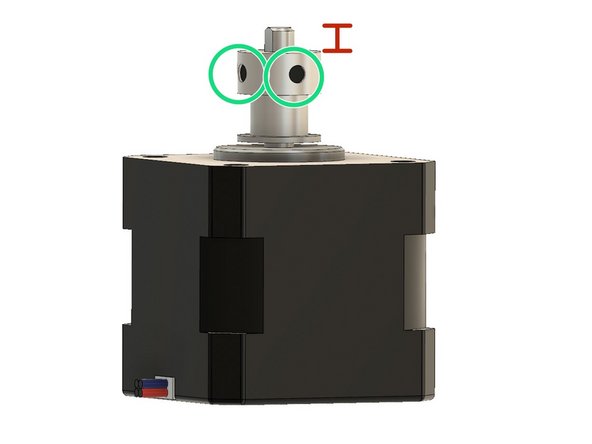

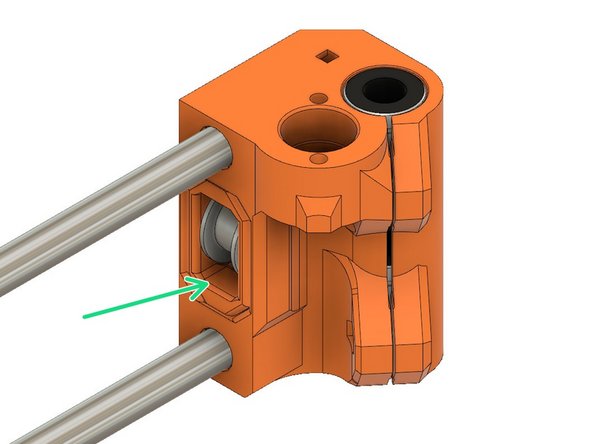

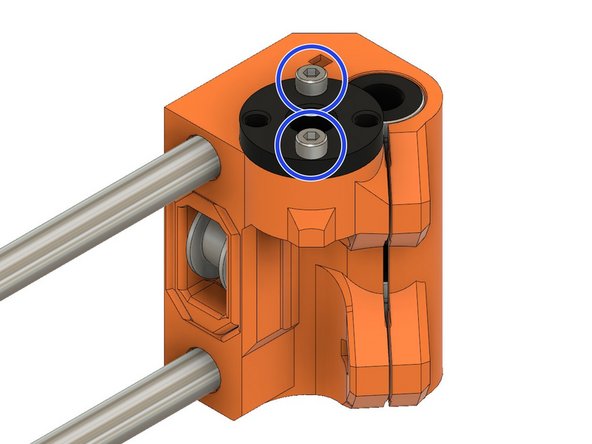

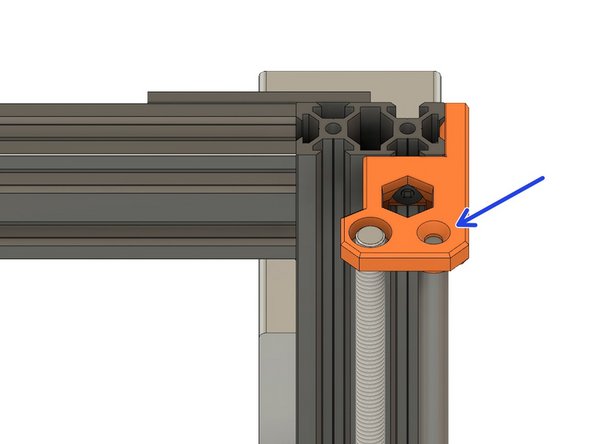

Insert an M3x18mm socket head screw in one of the x_end_idler clamp holes. This screw helps insert the hex nut.

-

Using tweezers, hold an M3 hex nut so that it can be threaded onto the M3x18mm socket head screw. Tighten that screw until the M3 hex nut is firmly seated.

-

Remove the M3x18 socket head screw and repeat on the other clamp hole.

-

-

-

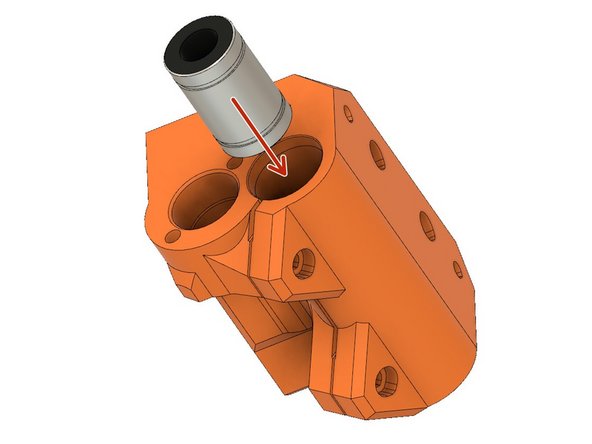

Insert an LM8UU linear bearing into x_end_idler until it hits the internal stop.

-

The next LM8UU linear bearing will have to be inserted so that the rows of balls are at 45° compared the rows in the other bearing.

-

Insert that LM8UU linear bearing until it hits the internal stop.

-

Verify that row of balls are rotated by 45° from each other

-

-

-

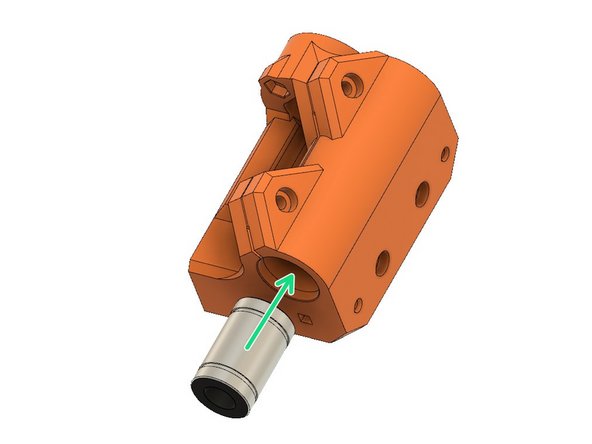

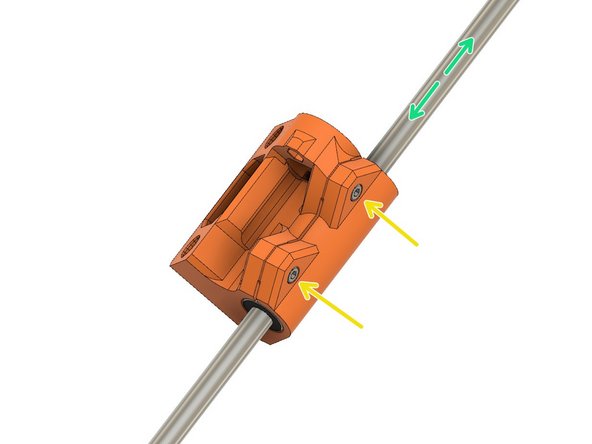

Temporarily insert a 8mm smooth rod through both LM8UU linear bearings.

-

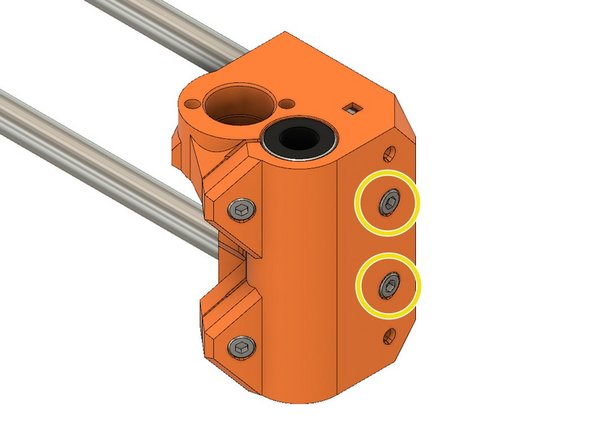

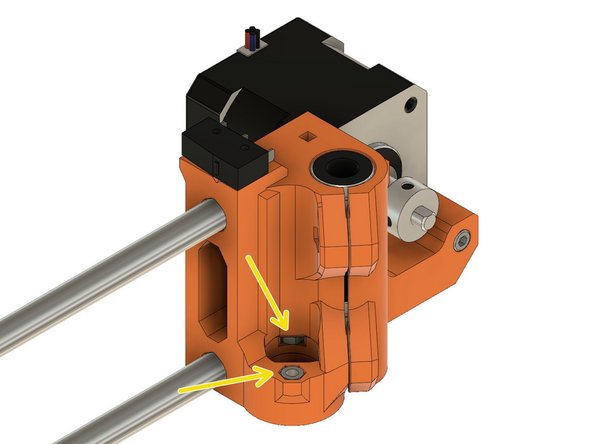

Engage two M3x10 socket head screws in the hex nuts, but do not tighten them at this time.

-

Alternatively tighten the two M3x10 clamp screws to secure the linear bearings. Slide the smooth rods back and forth while tightening.

-

Don't over-tighten the clamp screws; they need to be just tight enough to keep the bearings from moving.

-

Remove the 8mm smooth rod.

-

-

-

Repeat the 3 previous steps on x_end_motor

-

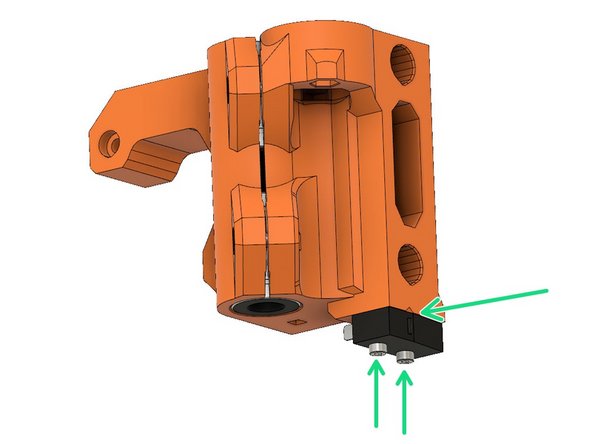

MK2s and MK2.5 only: Use two M2x12 screws to attach the x-endstop switch. Ensure the correct orientation of the switch.

-

MK2s and MK2.5 only: While tightening the screws, apply gentle pressure in the direction shown.

-

MK2s and MK2.5 only: Do not to over-tighten the M2x12 screws!

-

MK2s and MK2.5 only: Double check x-endstop switch orientation

-

-

-

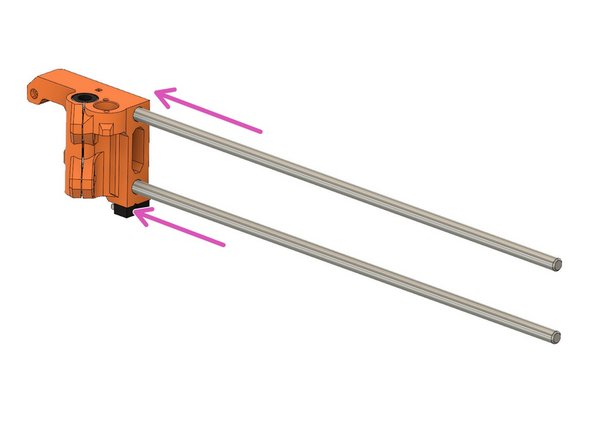

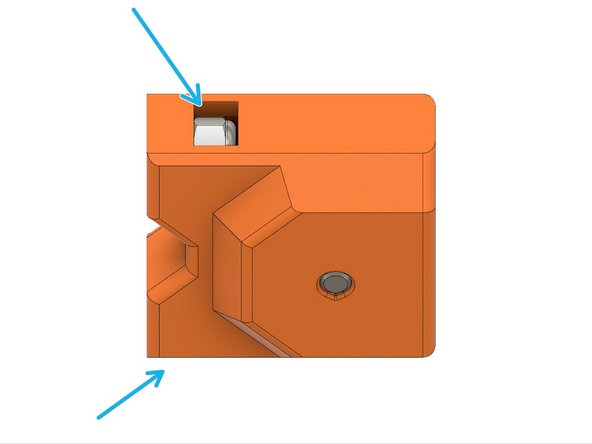

Check the x_end_motor holes for the smooth rods to ensure they are clean

-

Slide the two 370mm smooth rods in the x_end_motor.

-

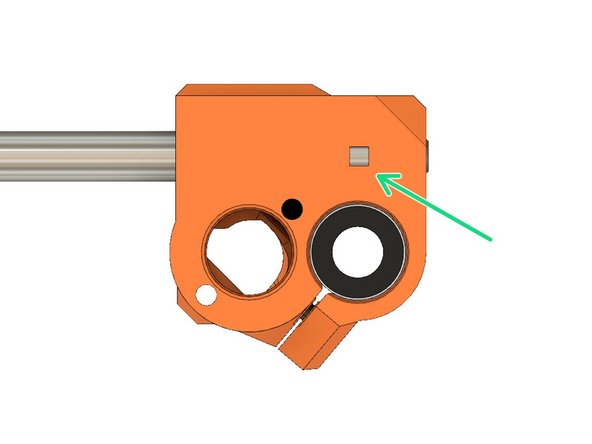

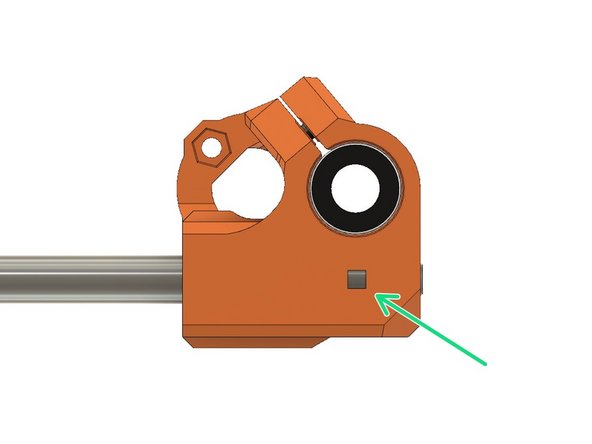

Ensure that the smooth rods are fully inserted. You can see them in the little windows on top and bottom.

-

-

-

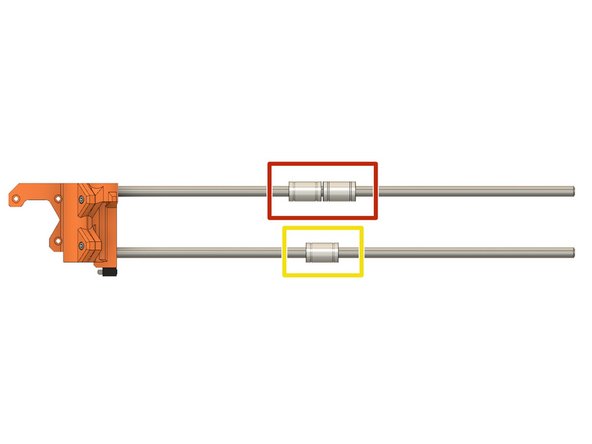

Insert two LM8UU linear bearings on the top smooth rod.

-

Insert one LM8UU linear bearing on the bottom smooth rod

-

Be very careful inserting the LM8UU linear bearings.

-

-

-

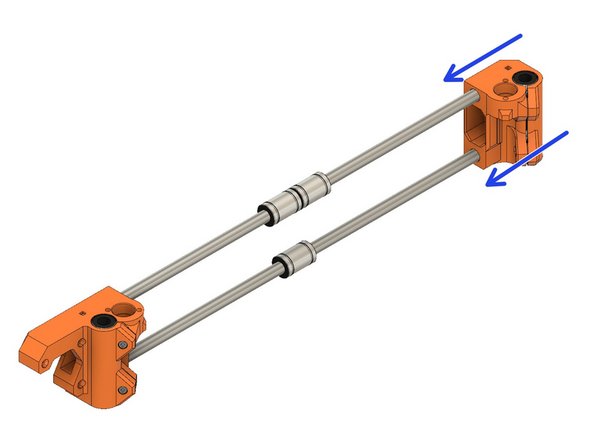

Insert both rods simultaneously into the x_end_idler and provide even pressure to force the rods all the way in.

-

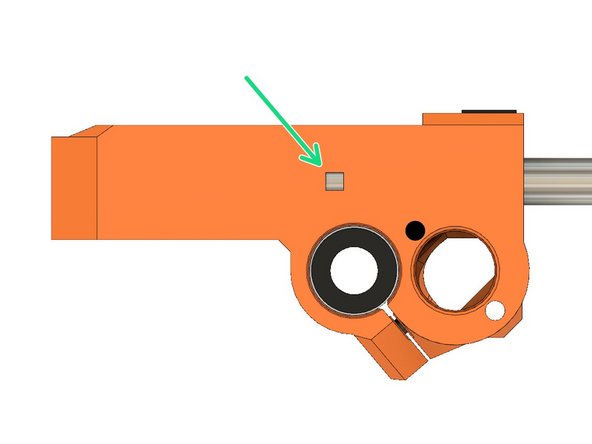

Using the observation windows, verify that each rod is fully seated.

-

Take the time to double check observation windows on both x_end_idler and x_end_motor.

-

-

-

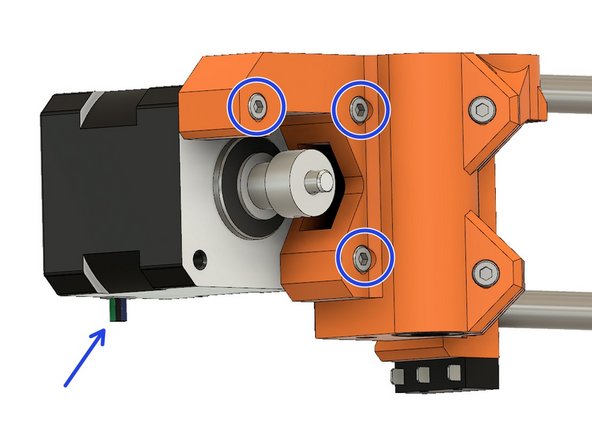

The 2GT 16T pulley grooves are not visible on the images

-

Position the 2GT 16T pulley so that approximately 3.5 to 4 mm of the shaft protrudes. Ensure the pulley is not touching the motor.

-

Align one of the set screws on the motor shaft flat and then tighten alternatively both set screws until they are both snug.

-

Using three M3x18 screws, attach the x-axis motor. Note the orientation of the wires.

-

Double check the pulley position and ensure it does not touch the motor

-

-

-

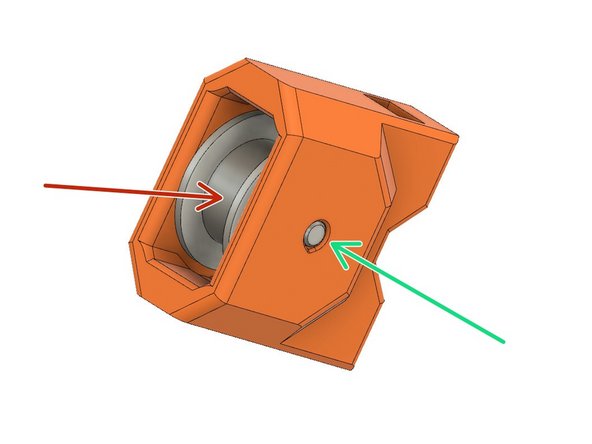

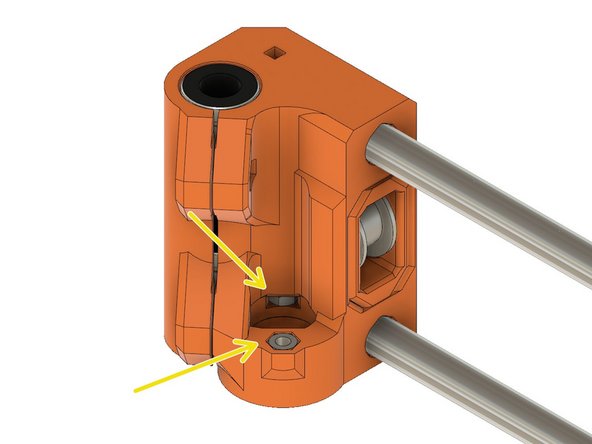

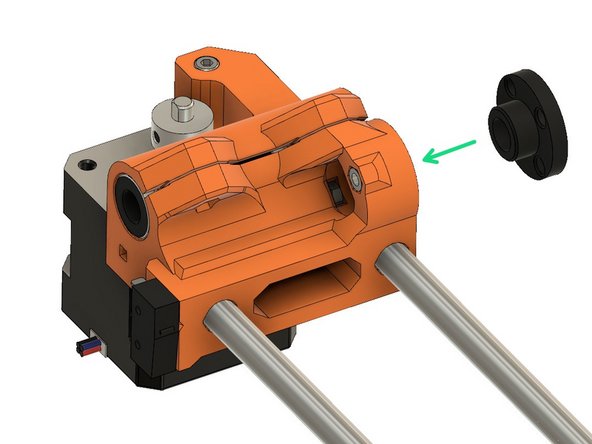

Insert the idler in the x_end_idler_idler_mount.

-

Press the dowel pin through the x_end_idler_idler_mount and idler bearings.

-

Verify that the dowel is not protruding from either side.

-

Verify that the idler spins freely.

-

Insert two M3 nylock nuts in the top and bottom of x_end_idler_idler_mount. Note the orientation of the nylock nuts.

-

-

-

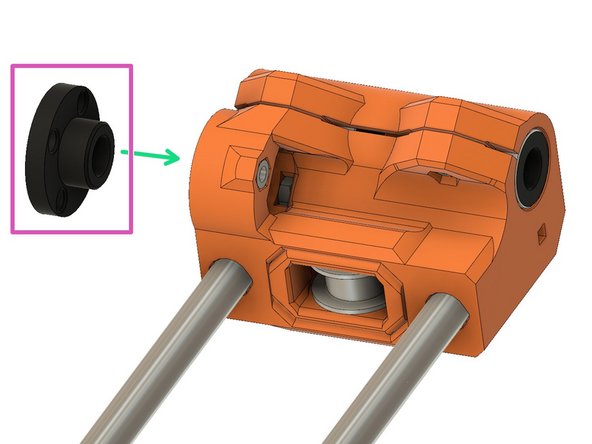

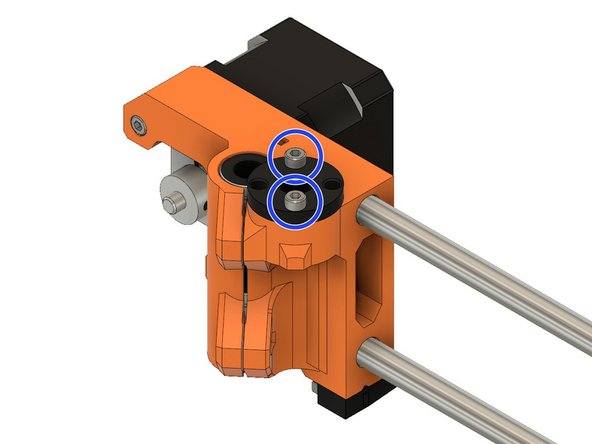

Insert the x_end_idler_idler_mount in the x_end_idler.

-

Secure it with two M3x18 screws. Don't tighten the screws, only engage them.

-

-

-

Insert two M3 hex nuts in the dedicated pockets of x_end_idler.

-

Note the orientation of the trapezoidal nut.

-

Insert a trapezoidal nut on top of x_end_idler.

-

Using two M3x18 screws, tighten the trapezoidal nut. Don't over-tighten the screws. They will be loosened and re-tightened after the x-end has been mounted on the z-axis rods.

-

Verify trapezoidal orientation.

Not a big deal, but it seems like it would be easier to install the trapezoidal nuts immediately following the linear bearing and endstop installation (before Step 6 - X Smooth Rods). It’s much easier to manipulate and orient the idler/motor end pieces to insert the required M3 hex nuts before everything is assembled into a heavier, more unwieldy unit.

Edward Wright - Resolved on Release Reply

Ok I take note, might change it later. I know I did it like that for a reason but can’t remember why :-D

-

-

-

Insert two M3 hex nuts in the dedicated pockets of x_end_motor.

-

Insert a trapezoidal nut on top of x_end_motor.

-

Using two M3x18 screws, tighten the trapezoidal nut. Don't over-tighten the screws.

-

Verify trapezoidal orientation.

-

-

-

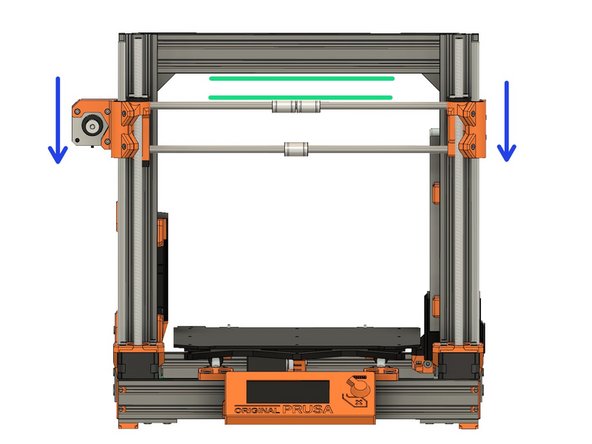

Check that z_tops and "z_end_caps" have been removed.

-

Carefully slide the X axis assembly onto the Z-axis. Rotate the lead screws to engage the X axis in the trapezoidal nuts.

-

Continue to rotate the lead screws with your fingers to move down the X axis assembly by few centimeters. If the X end is not parallel with the horizontal v-v-slot at the top of the Z axis, rotate one side to make the X axis assembly parallel to top of Z axis.

-

Continue to move the X axis assembly down to the middle of the Z axis. Keep the X axis as flat as possible

-

-

-

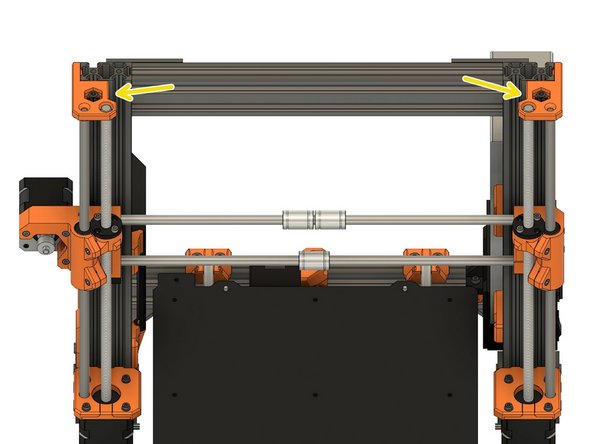

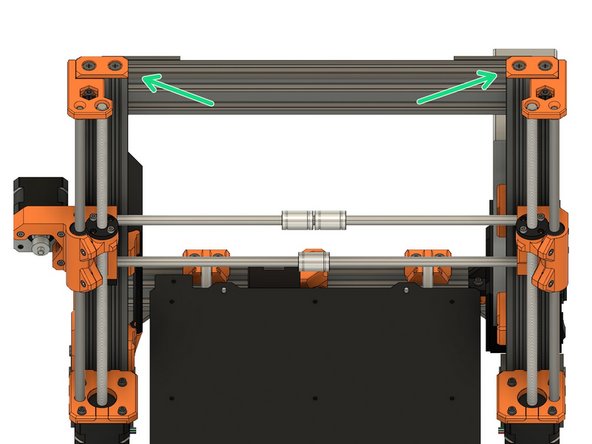

Install the z_tops with the two M5x10 screws and tighten them snug.

-

Make sure the z_tops are flush with Z smooth rods on both sides

-

Tighten the z_ends_caps on top of Z axis with the M5 screws.

-

-

-

Congratulations you have finished this chapter :-)

-

Go to the next chapter: 3. Extruder

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.

Cancel: I did not complete this guide.

One other person completed this guide.

2 Comments

I’ll second the 60 minute recommendation. It took me just over 50 minutes working slowly, carefully, and inspecting everything as I went, so rounding up to an even hour seems reasonable.

Edward Wright - Resolved on Release Reply