-

-

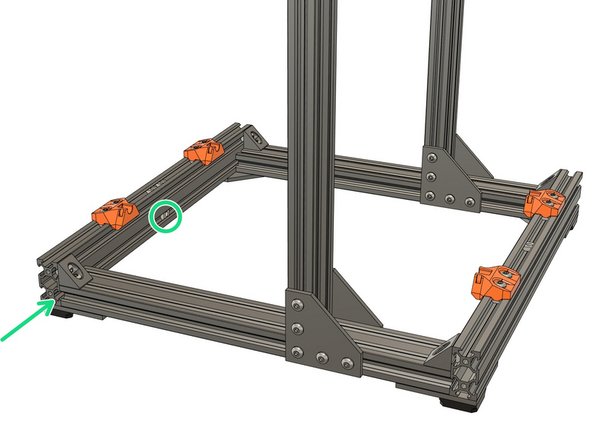

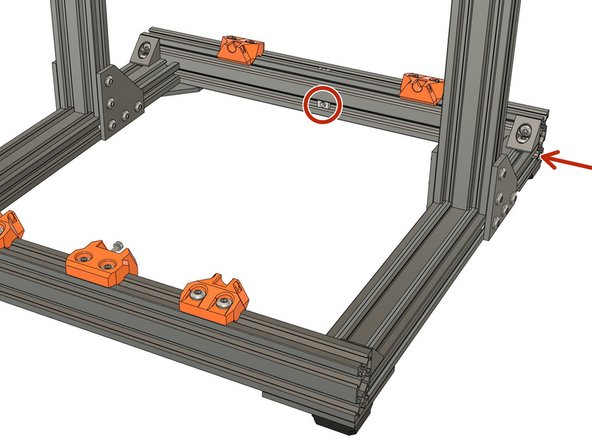

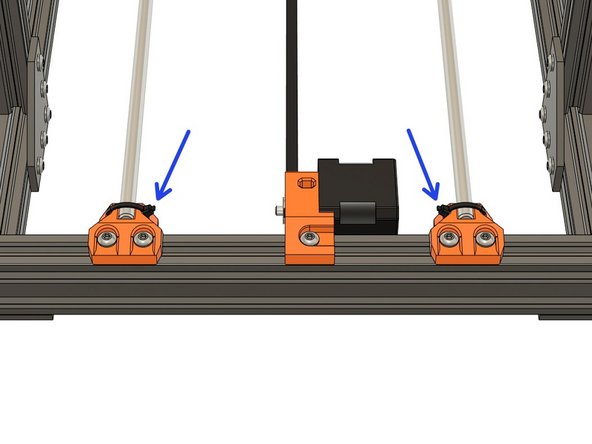

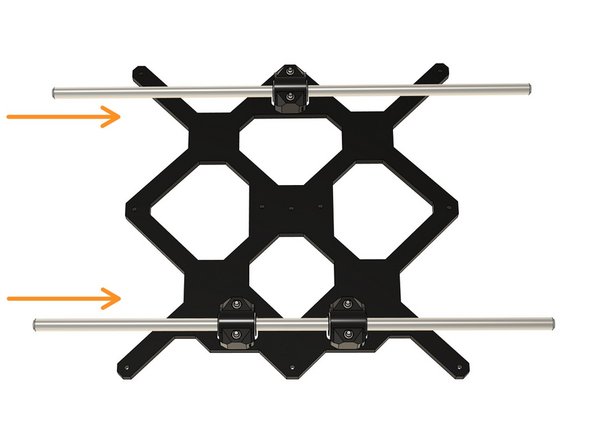

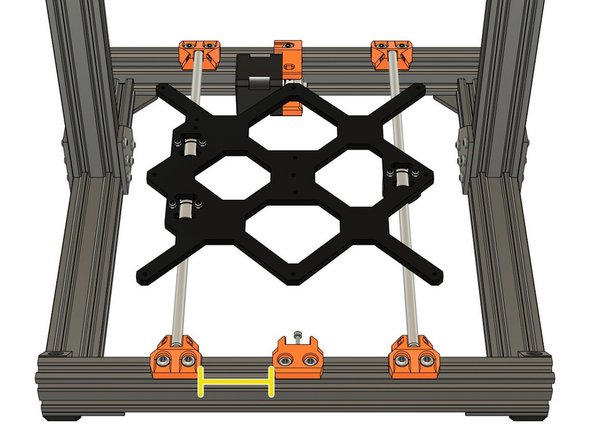

Slide 6x t-nuts in the top channel of the front extrusion.

-

Slide 5x t-nuts in the top channel of the rear extrusion.

-

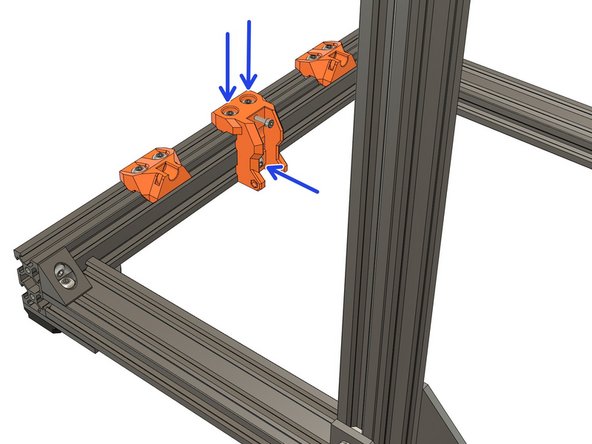

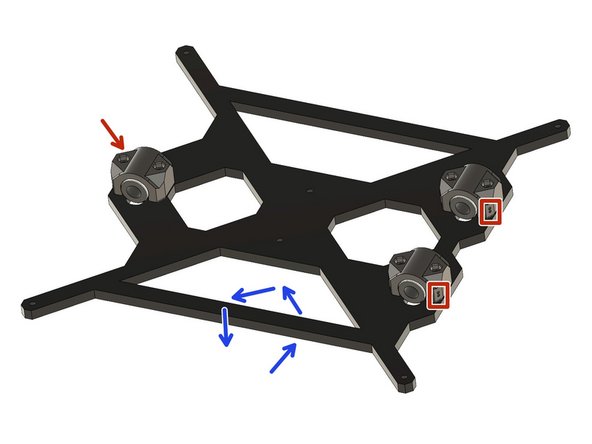

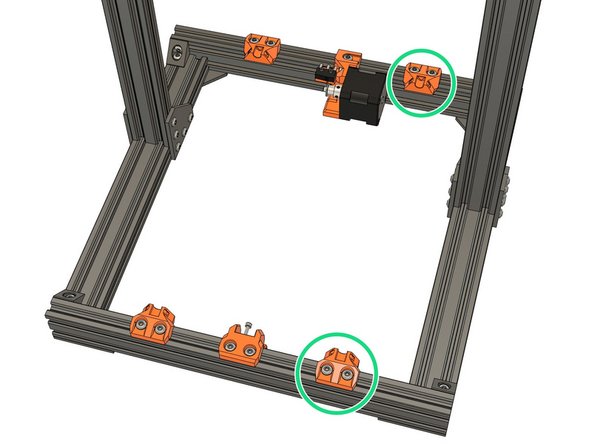

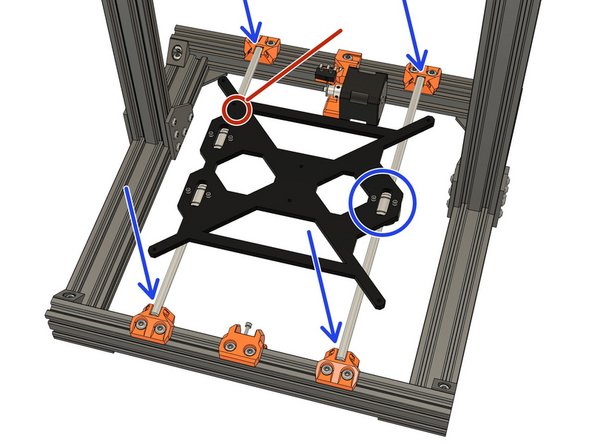

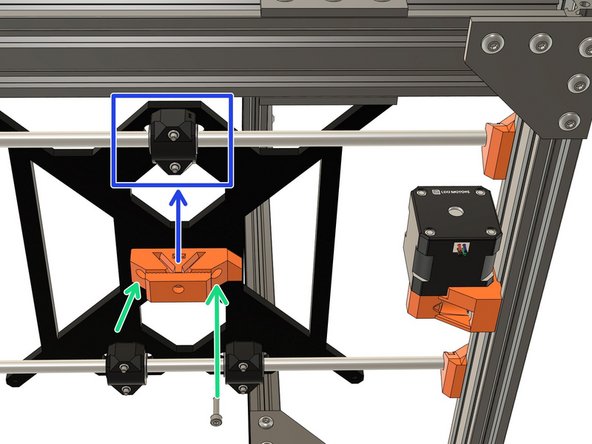

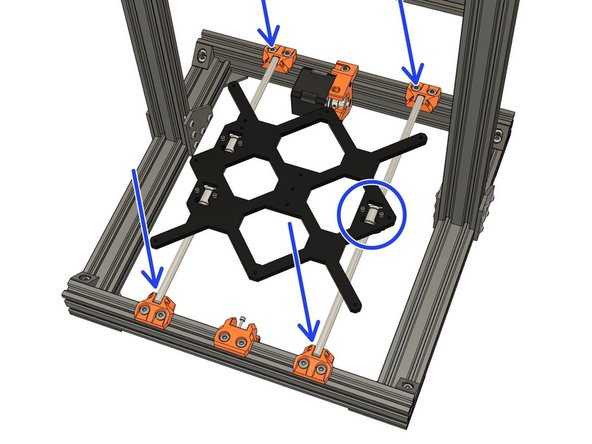

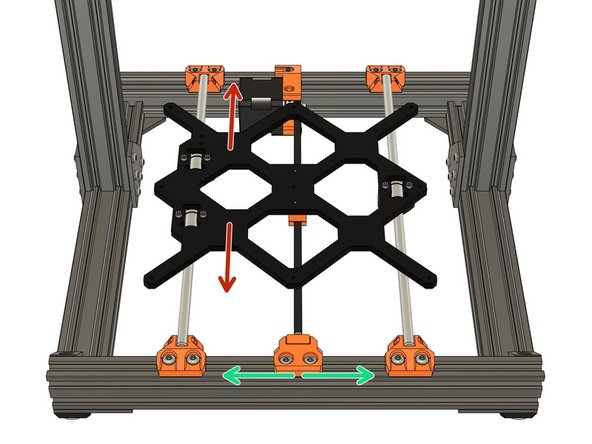

Attach 4x y_rod_holders to the frame, using 8x M5x12 screws, as shown. Tighten them just enough to prevent sliding, we will set the correct position later.

-

Check that you have have 2x free t-nuts in the top middle of the front extrusion and 1x free t-nut in the top middle of the rear extrusion.

-

-

-

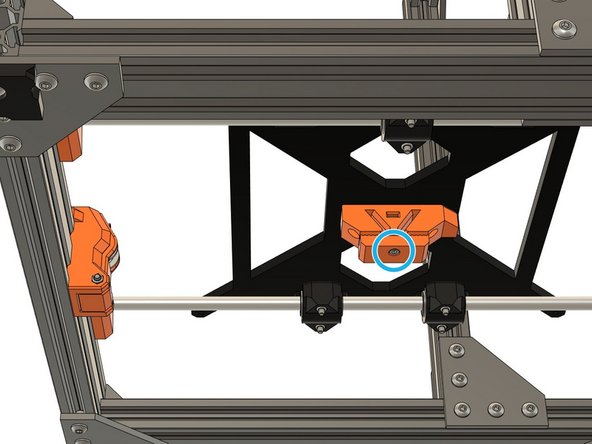

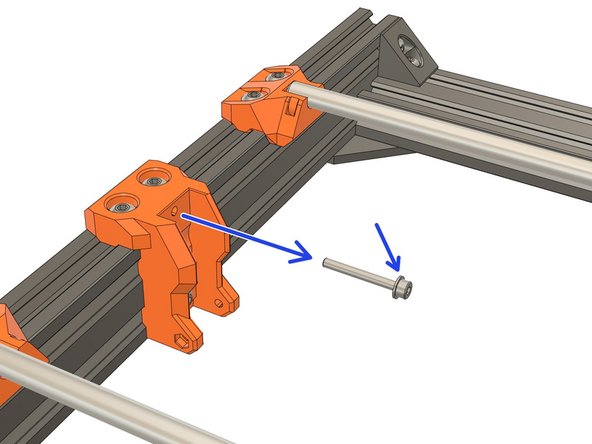

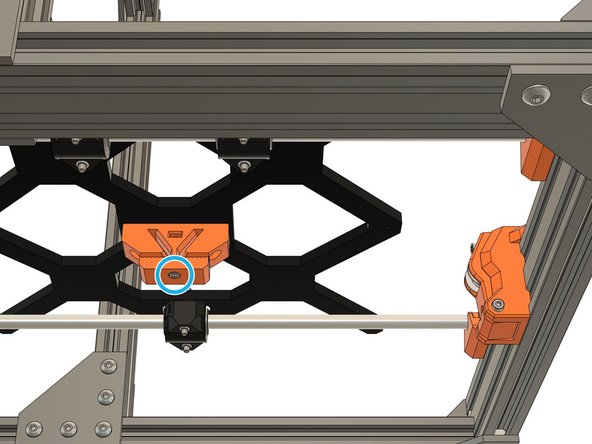

Take the "y_idler_mount"

-

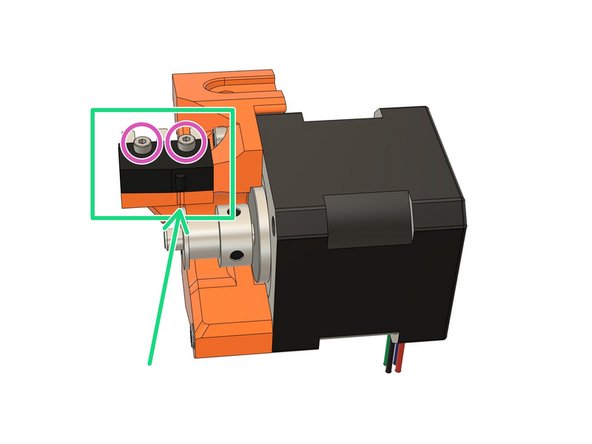

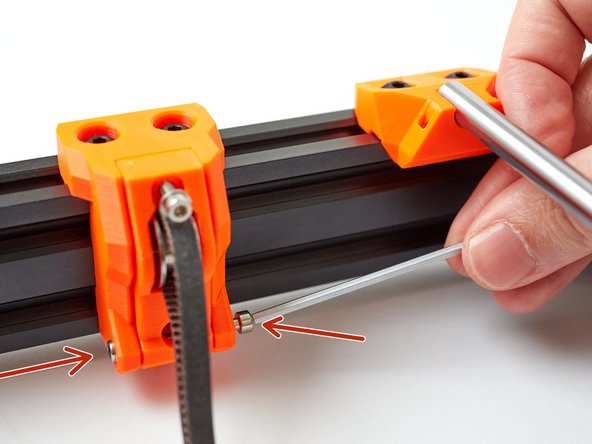

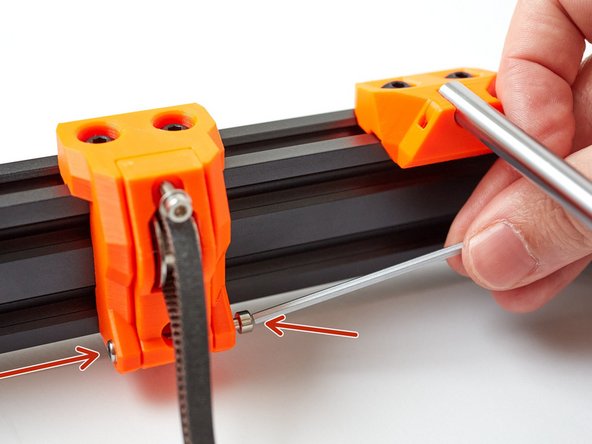

Place 1x M3 locknut in the pocket at the back of the part, as shown. Ensure sure the locknut has been fully inserted (use an Allen key or screwdriver) and is correctly oriented.

-

Thread 1x M3x25 screw through the front top hole and into the locknut. This will prevent you losing the locknut during the next steps.

-

I you have trouble to thread the screw you can remove the M3 nylock. Then take the M3x25 screw and thread the M3 nylock all the way through. Then remove it from the screw and repeat this assembly. This will make it slightly easier to screw in.

M3 nut pocket (the one for tensioner axis bolt) has too small diameter -standard M3 locknut doesn’t fit even if force is applied. I have loaded STL in FreeCAD and my measuring shows the inner diameter of about 5.37mm. This is too small, considering that the standard allows diameter to be between 5.32-5.50mm. I have modified STL (increased diameter to 5.6mm) and now M3 nut fits perfectly. Note: on 3D print, a hole should always be slightly bigger than actually needed.

My M5 holes are set at 5.3mm and this has been tested for several years with M5 screws. Make sure to calibrate your extrusion multiplier with our guide before printing the parts (and per spool). Check our guide here: Extrusion multiplier and filament diameter

I had difficulties since the printer put some supports and it was difficult to removed them. It results in a difficulty to insert the nut (I had to force thus the nut was not in the correct position, flat on top). At the end the nut was moving freely inside and no possibility to remove it. I put glue and it’s fine now. Maybe redesign the part so you can remove the nut from the bottom if it stuck

Étienne Vincent - Resolved on Release Reply

Hi Etienne, I will improve this part in the next design. Make sure to follow my print settings for the Bear parts or you might have trouble using them. You can find the print settings here: https://github.com/gregsaun/prusa_i3_bea... or from the main page here: Frame .

I also had trouble with the bolt slipping in the part. Some Nylock nuts can take a fair bit of force the first time they are used, I’d recommend putting an M3 bolt all the way through the nut first to make it slightly easier the second time so it doesn’t put as much force on the part.

Paul Arden - Resolved on Release Reply

Maybe locknut pocket should be redesigned. It is a bit hard to find m3 locknuts in North America. I tried to use regular m3 nut and as a result it damaged the walls of the pocket and now spins freely.

A more easier to source design might have square nut instead of locknut — it will stay in place and it’s been used in prusa design, so anyone upgrading their printer might have a few spare.

Alex Volkov - Resolved on Release Reply

Locknut is important here to avoid the belt tension changing over time due to vibrations. The official kits are coming with nylock and you can also reuse some from the Original Prusa printer.

-

-

-

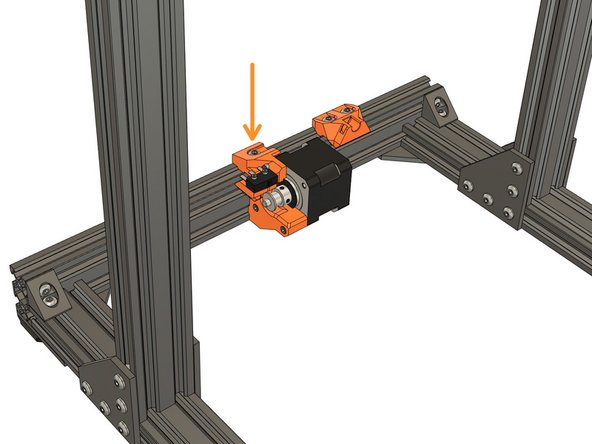

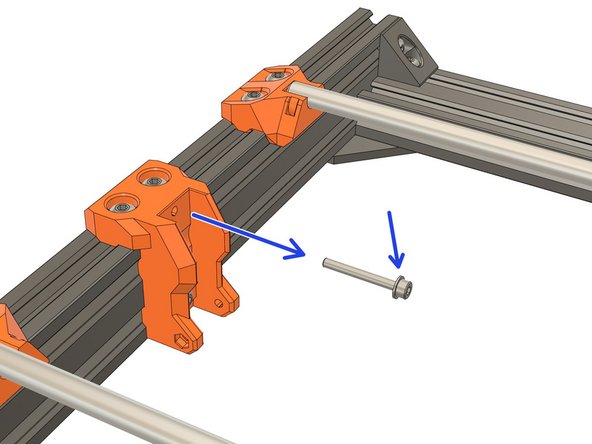

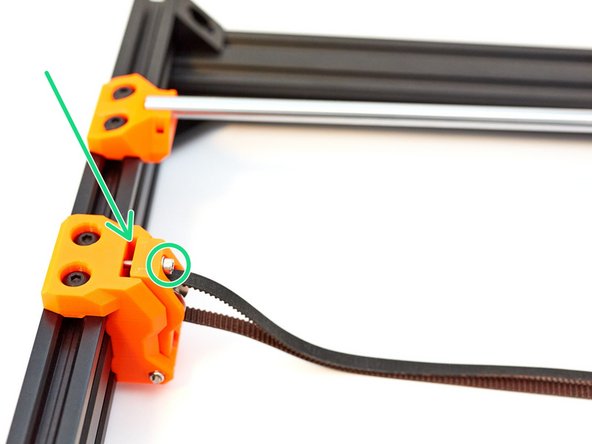

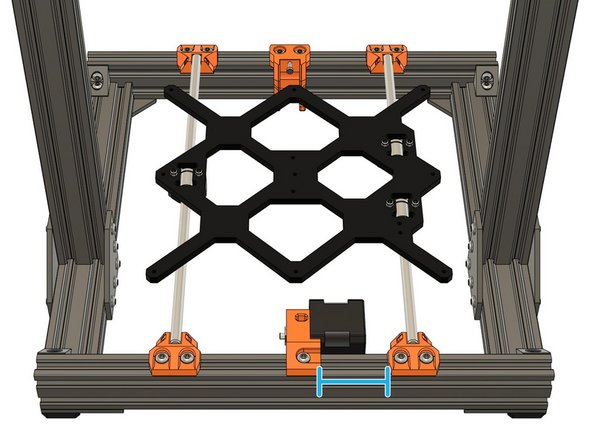

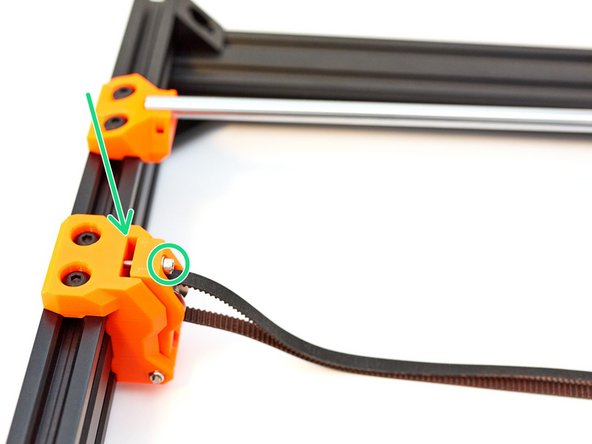

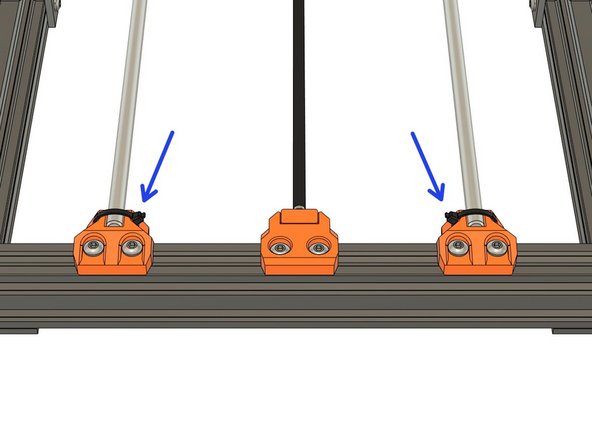

Slide 1x t-nut in the lower channel of the front extrusion, as shown.

-

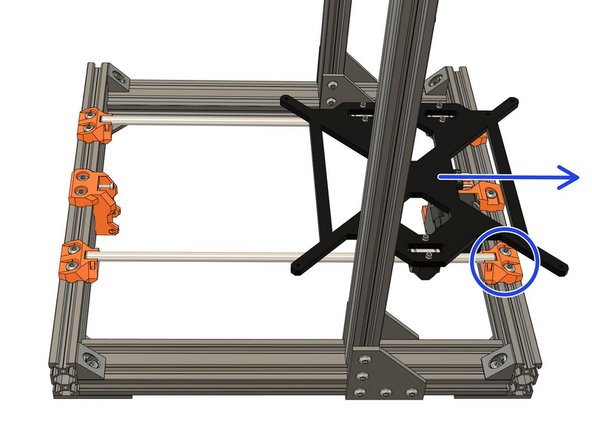

Using 3x M5x10 screws, assemble the y_idler_mount. Tighten them just enough to prevent the part from sliding. We will set the correct position later.

-

Do not fully tighten the part to the frame. We will adjust its final position when we align the belt path with the bed and motor.

"y_idler_mount" or “y_rod_holders” could be redesigned so that only one type of screw is needed (M5x12 or M5x10) and thus BOM is reduced.

Schrödingers Cat - Resolved on Release Reply

-

-

-

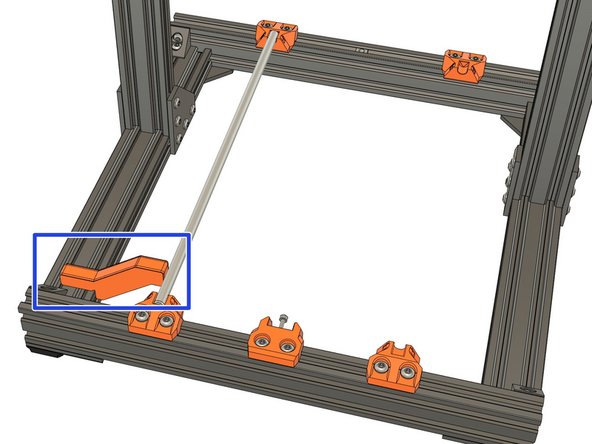

Take your time with this step, it could affect the alignment of the heatbed later.

-

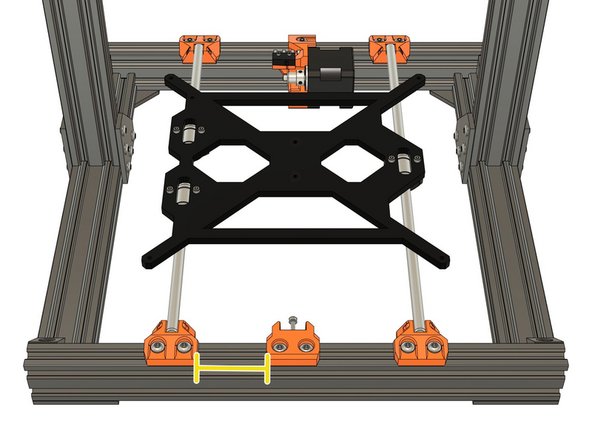

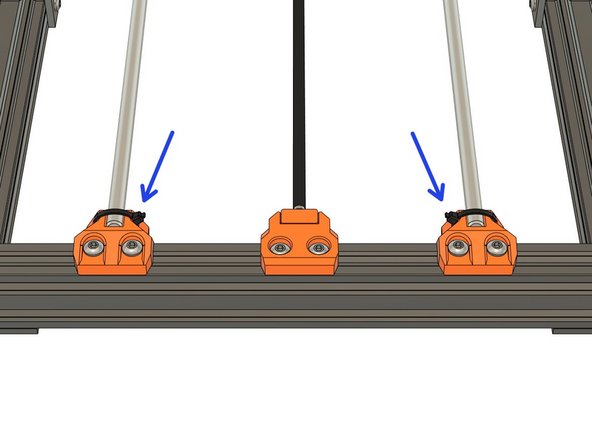

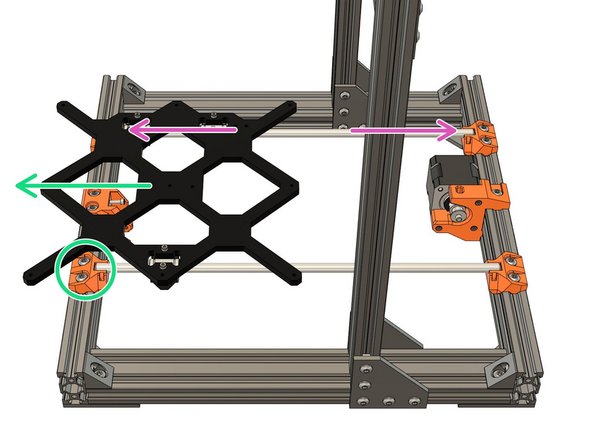

Clip 1x Y smooth rod (330mm long) into the y-rod holders, on the left-hand side.

-

Loosen the 4x M5x12 screws so that the y_rod_holders move easily.

-

Using the y_build_helper, adjust the position of the front y_rod_holder. Once the alignment is correct, fully tighten the M5x12 screws.

-

Make sure the y_build_helper is correctly seated against the extrusion and is in contact with the smooth rod.

-

Using the same y_build_helper, adjust and tighten the rear y-rod holder.

-

Carefully check the alignment of the front and rear of the smooth rods. You may need to repeat the adjustment to get them perfectly aligned.

depending on the material you used for the print, it is way easier with some lub (the one I use for the bearings anyway)

Étienne Vincent - Resolved on Release Reply

Would I be correct in thinking that the outside of the left metal rod is 96mm from the outside edge of the frame (56mm from inner edge of frame)?

This dimension can be slightly different from every frame depending the assembly so it is better to use the build helper and this assembly guide. In case of you can find the dimensions here for MK3(S) and here for MK2(S)/MK2.5(S) .

-

-

-

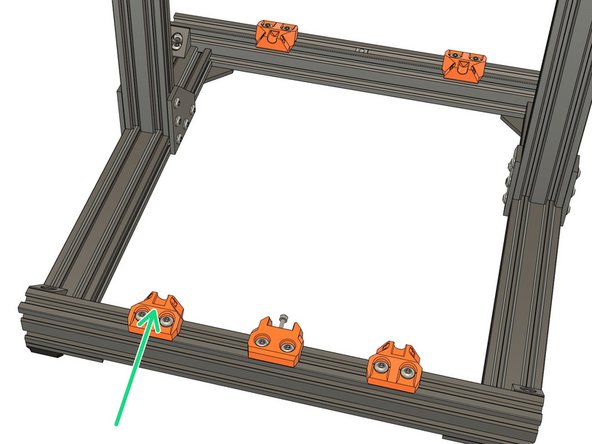

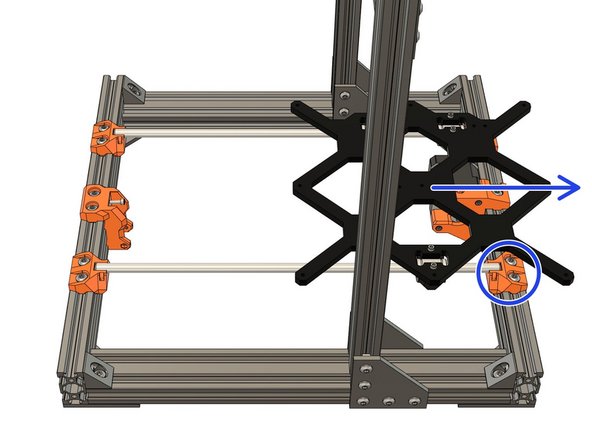

Remove the Y smooth rod you installed in the previous step.

-

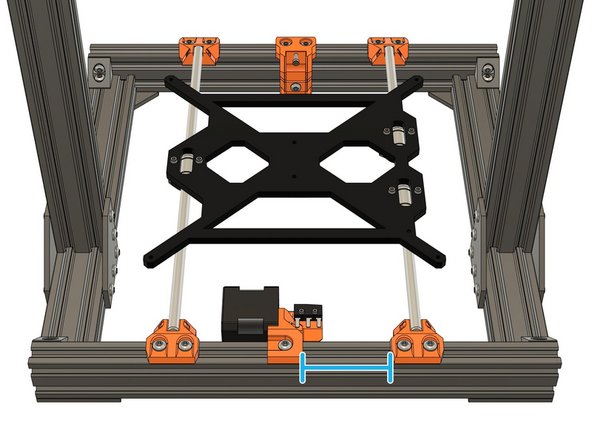

Slide 1x t-nut into the lower channel of the rear extrusion, as shown.

-

Be careful that this this t-nut does not fall out during the following steps. (Remember the tape / Blu Tack tip)

-

-

-

We are now going to prepare a few parts that will be used later in this chapter. Let's start with the Y bearing holders.

-

If you come from an Original Prusa MK3S+ you can reuse the black metal bearing clip instead of the printed ones and skip this step and the next one.

-

Take the 3x y_bearing_holder and insert 2x locknuts in each of them, 6x locknuts in total (reused from your Original Prusa). Those locknuts need to be reused from your Original Prusa printer.

-

We need to make sure that the locknuts are fully inserted in their pocket. To do this, take 1x M3x18 screw and 1x washer.

-

For each locknut in the y_belt_holders, insert the screw and tighten it against the washer, until the locknut is fully seated.

-

Remove the screw and washer and repeat for the 5 other locknuts of the bearing holders.

-

Make sure the 6x locknuts are fully seated in the bearing holders.

-

-

-

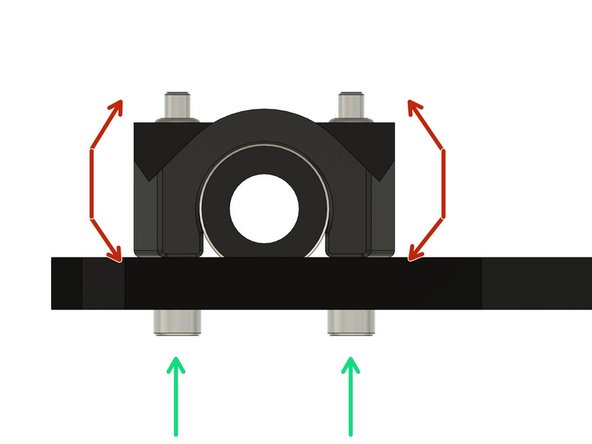

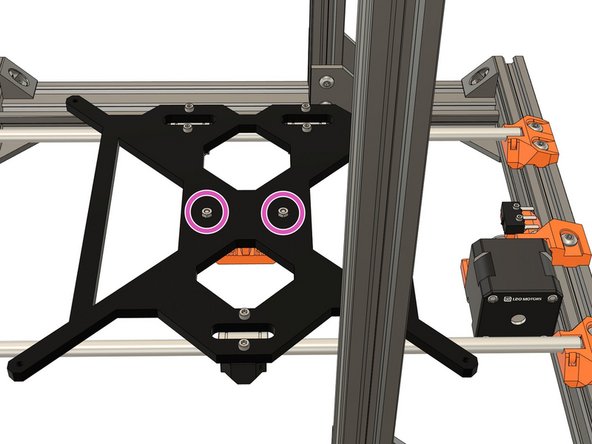

We are now going to insert the LM8UU bearings in the 3x y_bearing_holders. When you place the bearings you need to ensure that the rows of ball bearings are at 45° as shown in the image.

-

Insert the LM8UU bearings in the each of the 3x y_bearing_holders. Each bearing should be centred in the bearing holder. There are ridges in the plastic part which will align with the grooves in the LM8UU bearing.

-

Confirm that each bearing is aligned vertically as shown in the first image. It is very important to have all x3 bearings correctly aligned!

-

Keep the 3x y_bearing_holders ready for use later in this chapter.

The m3 screw and washer need to be removed prior to inserting the bearings as otherwise the washers interfere with the bearing going into the socket. Perhaps move this step to be prior to seating the lock nuts?

-

-

-

The part you use in this step, might look different to that shown in the instructions, depending on which Prusa variant you are building. However, the following instructions are the same for each variant.

-

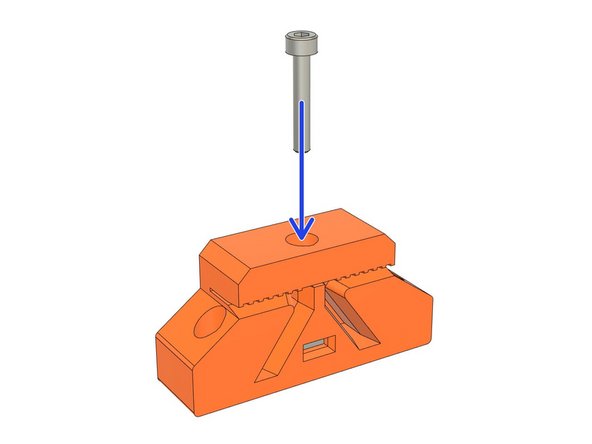

Insert 1x square nut into the y_belt_holder, as shown.

-

Thread in an M3x18 screw, from the top. Do not tighten it yet.

-

Keep the y_belt_holder for later use.

-

-

-

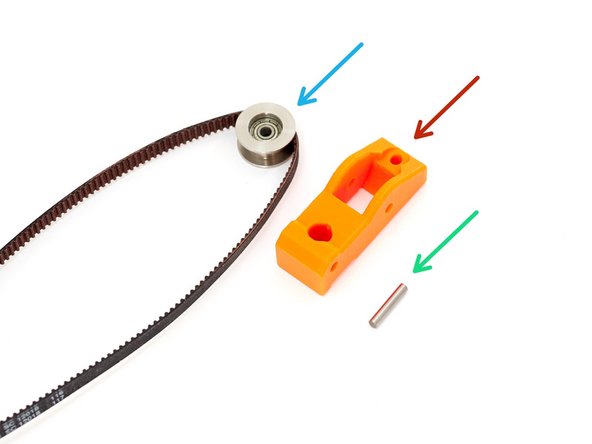

Prepare the following parts:

-

1x 20T idler with Y axis belt (650mm) looped around it.

-

1x y_idler_tensioner printed part.

-

1x dowel pin.

-

Place the belt around the idler and insert it into the y_idler_tensioner.

-

Insert the dowel pin from the right side. Make sure the dowel pin is fully inserted and does not stick out of the y_idler_tensioner

-

Keep the y_idler_tensioner for use later.

20T Idler is a Smooth Idler pulley without Teeth or with Teeth ?

Rajavel Bhasker - Resolved on Release Reply

tips: i didn’t had an idler, so I cut the head of a M3 screw with a metal saw

Étienne Vincent - Resolved on Release Reply

other alternative to dowel pin: M3 x 16 countersink head screw. Use a 6mm drill to create a countersink on one side of y_idler_tensioner so screwhead is flush with surface

I attempted this and accidentally drilled through the printed piece. Take it slow if you go this route.

If you don’t have dowel pin, you can use 2.8mm rod, 17mm length. Or use the following openscad design.

cube_dim = 5;

rod_h = 17;

difference(){

cylinder(d=2.8, h=rod_h, $fn=20);

translate([-cube_dim/2, 1,0])

cube([cube_dim, cube_dim, rod_h]);

}

Alex Volkov - Resolved on Release Reply

-

-

-

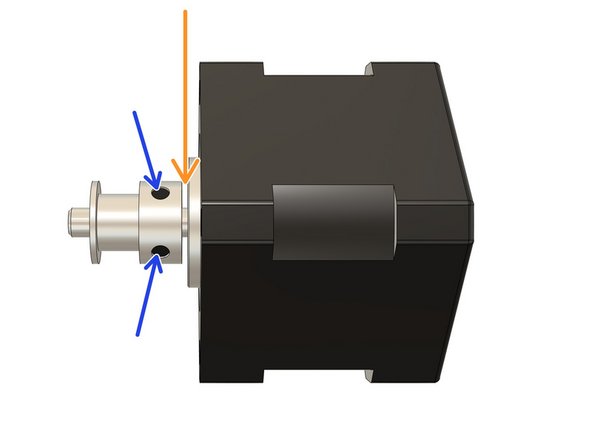

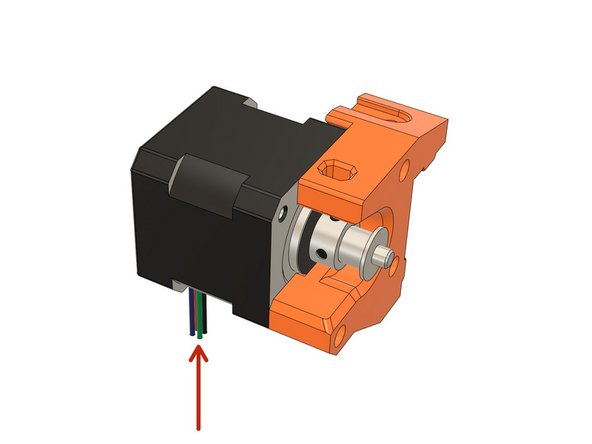

Take the Y axis motor.

-

Slide the 16T drive pulley on to the motor shaft, as shown. Make sure the pulley is not touching the motor (around 1mm of space between the motor body and drive pulley is enough).

-

Make sure the grub screws are both tight, ensuring that one of the grub screws is tightened against the flat part of the shaft.

-

Keep the Y motor for later use.

I'm building the fysetc and the motors are not labeled. Any idea which I should use at this step?

pleaae could you indicate which of the stepper motors is for the y axis? 17HD2201Z-22B-700 OR the 350 or the 500?

Matt Ratcliffe - Resolved on Release Reply

my motor’s shaft’s flatness doesn’t go deep enough to be able to leave only 1mm gap and have one of the grab screws tightened against the flat surface. In the closest position I have 5mm space and cannot go lower.

I suppose a 1mm “feeler” gauge could be added to the helper tools for this step?

I have designed something in the past, I will add it in the next release, good idea.

Is thread locker on the grub screws helpful? I’ve actually had the this pulley manage to slip on a mk3.

Nice to have I agree. You can find the thread locker recommendation in the optional tools of the first chapter.

-

-

-

The next steps are for MK2(S) or MK2.5(S) printers only.

-

If you have MK3(S) jump to step 26.

-

-

-

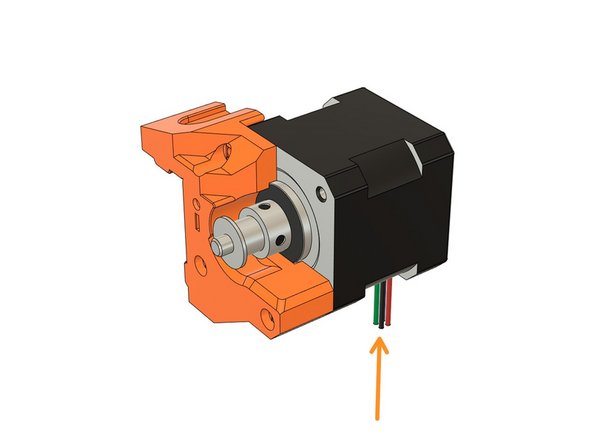

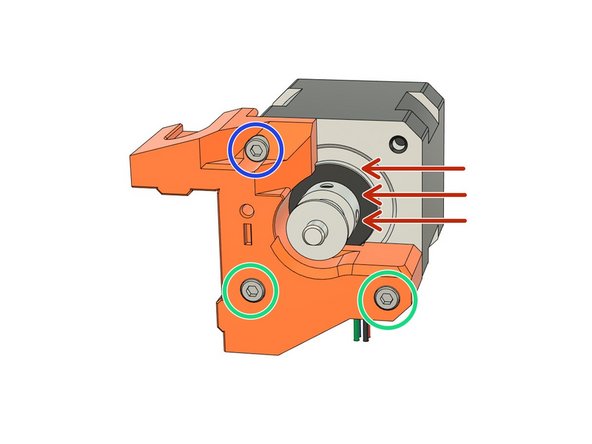

Place the Y motor on the y_motor_mount as shown in the first image. The cables must be orientated downward.

-

Secure the motor with the following screws. Do not fully tighten them yet.

-

2x M3x18

-

1x M3x10

-

Whilst pushing in the direction shown, fully tighten all 3 screws.

-

Check that the motor cables are oriented correctly.

-

-

-

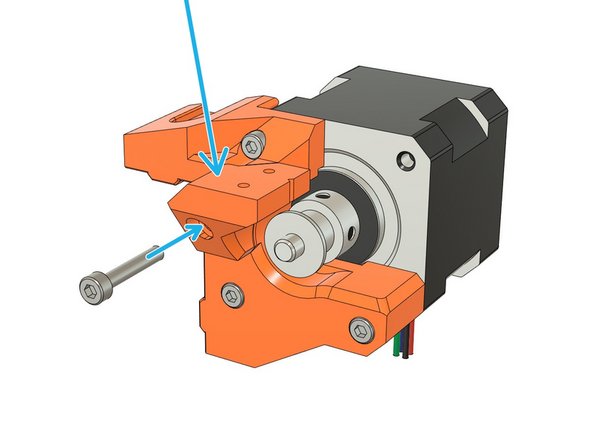

Place the y_motor_endstop_mount, as shown, and secure it with 1x M3x18 screw.

-

Place the Y end stop on the y_motor_endstop_mount with the switch actuator aligned with the notch, as shown.

-

Make sure the orientation of the switch is correct!

-

Insert and tighten 2x M2x12 screws to secure the end stop. Do not over tighten these screws, otherwise you may damage the end stop.

-

If it is too hard to tighten the M2 screws into the end stop mount, you may use a 1.5mm drill bit to clear the holes. Be careful that you do not break the drill bit.

I’m I the only one with M2 screws not screwing in? maybe the printing was too large

Étienne Vincent - Resolved on Release Reply

-

-

-

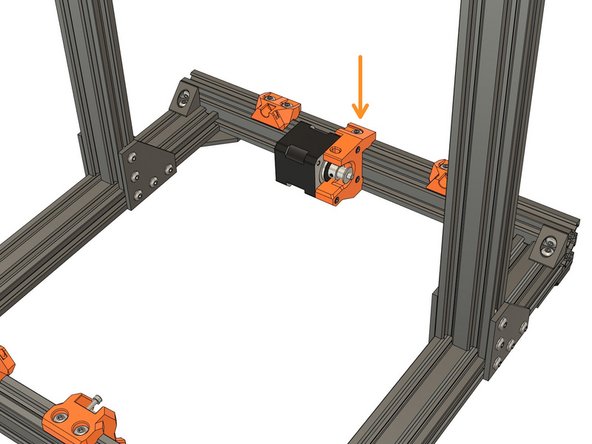

Install the y_motor_mount on the extrusions in the back. Do not fully tighten the screws. We will set the position in Step 19.

-

1x M5x12 on top

-

1x M5x16 on bottom

-

Always tighten the y_motor_mount screws evenly, incrementally and in turn. This ensures that the motor mount is properly square on the extrusions.

it is maybe an error but I didn’t have a M5x16 screw in the package, I had to buy a stock of M5x15. It would be nice to use the same M5x12 screw as the other parts

Étienne Vincent - Resolved on Release Reply

Make sure to calibrate your extrusion multiplier before printing the Bear parts. We have made a guide here: Extrusion multiplier and filament diameter . Also important to follow the print settings.

-

-

-

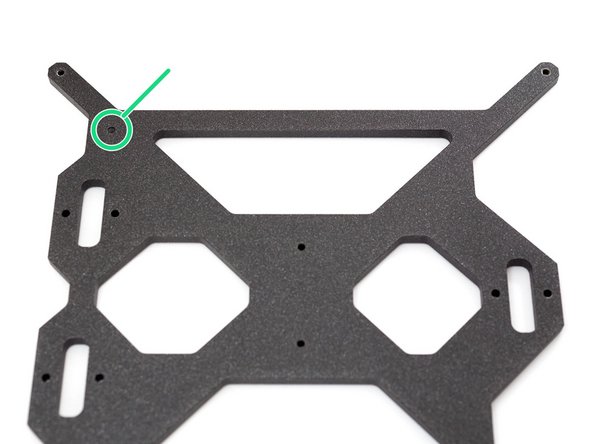

Locate the marker of the Y carriage.

-

Flip the carriage to have the marker facing the table (not visible anymore in the 2nd and 3rd image).

-

The y_bearing_holders have 2 dots printed on one of their corners. Place the 3x y_bearing_holders with the dots oriented as shown on the 2nd image.

-

Double check the orientation of the y_bearing_holders, this is important as you might have issues later with the heated bed.

-

Secure the bearing holders with 6x M3x25 screws. Do NOT tighten them yet!

I forgot to check the orientation of the y_bearing_holders during setup - and of course - put them the wrong way. However they look simmetrical to me and they are working just fine also with dots pointing “inside”. Why is it important to match the orientation?

Filip Karas - Resolved on Release Reply

-

-

-

Take your time with this step. It is important that it is done correctly or it can cause issues later with your printer. Do not over-tighten the bearings or you may cause permanent damage to them.

-

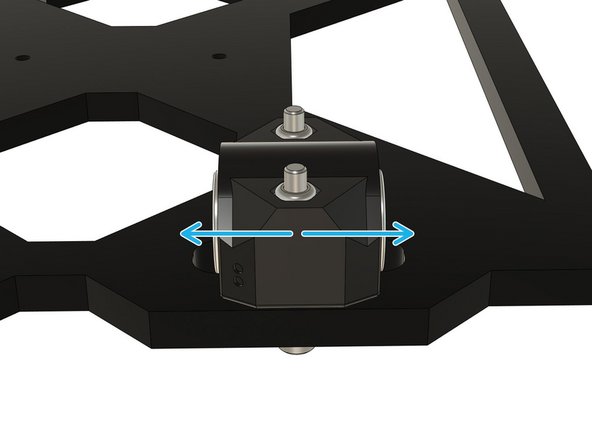

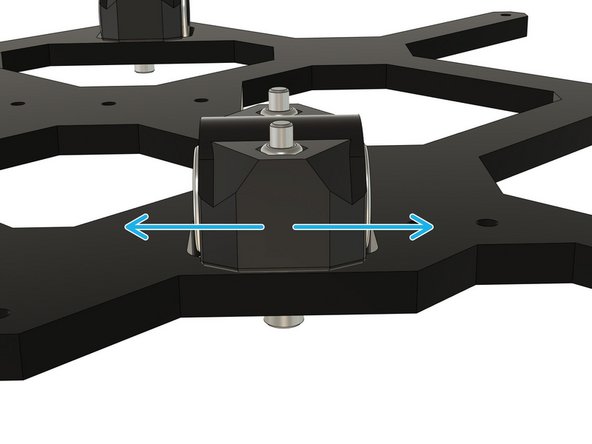

Start tightening evenly, incrementally and in turn. the M3x25 screws. While tightening, test if the bearing can rotate in the directions shown by the red arrows. When it no longer moves, in this direction, stop tightening immediately.

-

Check whether the bearings can slide along the slot.

-

If the bearing can slide: tighten evenly, incrementally and in turn, the M3x25 screws until you can't move it anymore. Do not over-tighten!

-

If the bearing is not moving anymore: continue to the next bearing.

-

Repeat this step for the two remaining bearings.

-

-

-

Gently insert 2x Y axis smooth rods (330mm long).

-

You must not use any significant force whilst inserting the rods into the linear bearings.

-

Don't rotate the smooth rods, the LM8UU bearings are not made to rotate.

-

Loosen the M5 screws of the 2x right y_rod_holders. You should be able to slide them easily by hand.

-

Clip the Y smooth rods and carriage assembly into the y_rod_holders. The Single bearing should be to the right.

-

Verify the marker on the carriage is correctly positioned. If this is not the case, check that you have followed the previous steps correctly.

-

It is very important to have the LM8UU bearings correctly oriented as well as the marker or you will have issues later in the assembly.

-

-

-

Take your time with this step.

-

Move the Y carriage, backwards and forwards along the whole length of the Y axis, at least 6 times. This will align the right smooth rod (single LM8UU side).

-

Move the Y carriage to the front and tighten the screws for the right-front y_rod_holder evenly, incrementally and in turn.

-

Move the Y carriage to the back and tighten the screws for the right-back y_rod_holder evenly, incrementally and in turn.

-

Never use the build_helper_y with the right smooth rod, it is made to align left smooth rod only (dual LM8UU side).

-

Tech tip: If you have a 200mm caliper you can measure the distance from the smooth rods directly on the metal. The spacing of the smooth rods is 170mm, the diameter of smooth rods is 8mm, which means the external spacing you should measure will be 170 + 2*8/2 = 178mm.

-

-

-

Set the y_idler_mount and y_motor_mount position as following:

-

47mm for the y_idler_mount.

-

61.5mm for the y_motor_mount.

-

We will adjust these positions, if necessary, after the belt is in place and tensioned.

-

-

-

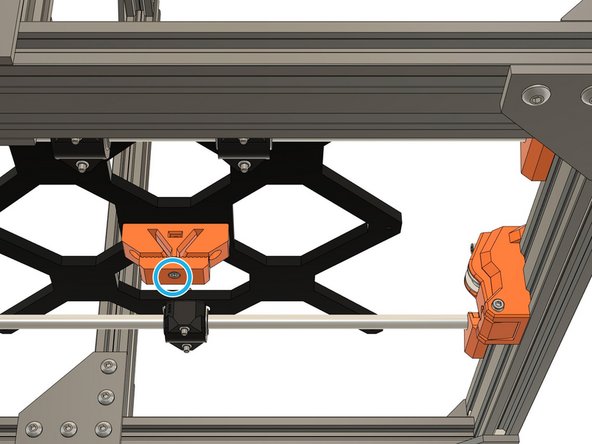

Install the y_belt_holder under the Y carriage. The grooves should face the single bearing side.

-

2x M3x12 (reused from your original Prusa).

-

2x M3 hex nut. Note that these nuts will be removed when installing the heated bed, they are only temporary.

-

Check the orientation of the y_belt_holder.

-

-

-

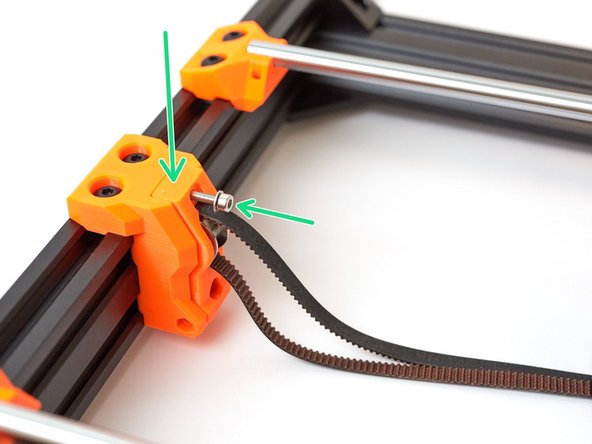

Remove the M3x25 screw, used during installation, from the y_idler_mount and add a washer to the screw.

-

Insert the y_idler_tensioner into the y_idler_mount and reinsert the M3x25 screw with its washer.

-

Insert an M3 locknut into the left side of the y_idler_mount and thread an M3x30 screw from the other side. Use this screw to help seat locknut correctly, in the part. Do not over-tighten this screw, the y_idler_tensioner should move with almost no resistance.

-

Confirm you have a washer on the M3x25 tensioning screw.

-

Check that the y_idler_tensioner can move with almost no resistance.

The hole for the locknut on the side of the tensioner was too tight for my M3 nyloc nuts and hence the nut broke the printed model. Consider increaring the width of that cutout by 0.2 mm - that worked for me well.

Gabor Penoff - Resolved on Release Reply

I also had difficulties setting the nylock nut. Maybe moving this part up the step 2 (before mounting on the frame) would be helpful since the user can use a flat surface to help push it in.

Ruxi -

Sorry you had difficulties with this part. I have taken note of that issue for future improvement.

-

-

-

Unscrew the idler tensioner screw until there is a small gap (around 3mm).

-

Unscrew the clamp of the y_belt_holder to help the insertion of the belt in the next step.

-

-

-

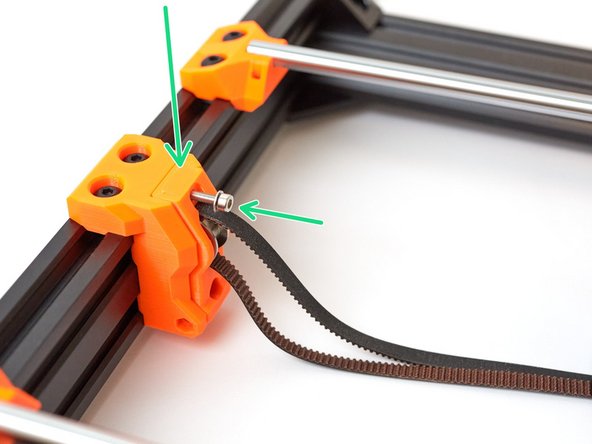

Insert the top section of the belt into the left side of the y_belt_holder. If necessary, use a small slotted screwdriver to help insert the belt. The belt should be inserted to the full depth of the groove .

-

Make sure the belt teeth are correctly oriented according to the shape of the y_belt_holder.

-

Continue to route the belt around the Y motor pulley and finish by inserting the belt into the y_belt_holder. The belt should have almost no tension, it will be adjusted later.

-

If the belt is too long to fit inside the y_belt_holder you can trim the excess.

-

Verify that the belt is fully inserted into the slot.

-

Tighten the M3x18 screw to secure the belt.

-

-

-

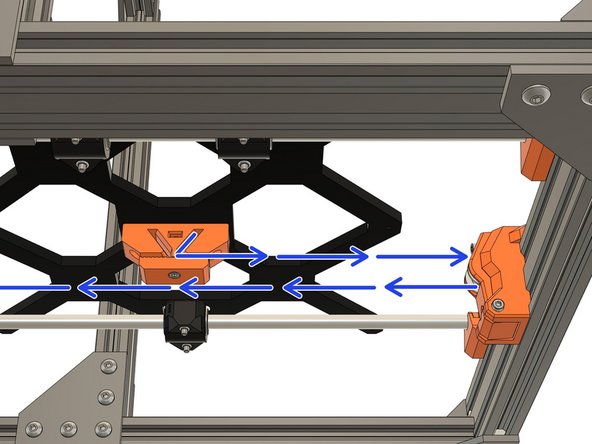

Apply a light tension to the belt to remove any slack. Do not over-tighten the belt or adjustments will be impossible.

-

We will adjust the belt, to the correct tension, in a later step.

-

Adjust the position of y_idler_mount and y_motor_mount using their M5 screws. Try to have the belt riding centred as best as possible on the pulley (motor side) and the idler (tensioner side).

-

It is important to move the Y carriage back and forth along the whole axis between each adjustment.

-

Remember that when you tighten the y_idler_mount and y_motor_mount screws you must do so evenly, incrementally and in turn. If you don't do this you may cause those parts to be misaligned.

-

-

-

Secure the Y smooth rods with 4 zip ties. Note the orientation of them.

Is the picture in Step 25 reversed from left to right? If I’m looking at this correctly, my motor is reversed from what is shown.

It is not, the MK3 and MK2/2.5 have the motor positioned differently. This is an image of the MK3 but the same orientation applies to zip ties.

-

-

-

Congratulations you have finished this chapter :)

-

Go to the next chapter: 06. Z axis motion

-

-

-

The next steps are for MK3(S) only until the end of this chapter.

-

If you are building a MK2(S) or MK2.5(S) jump to step 38.

-

-

-

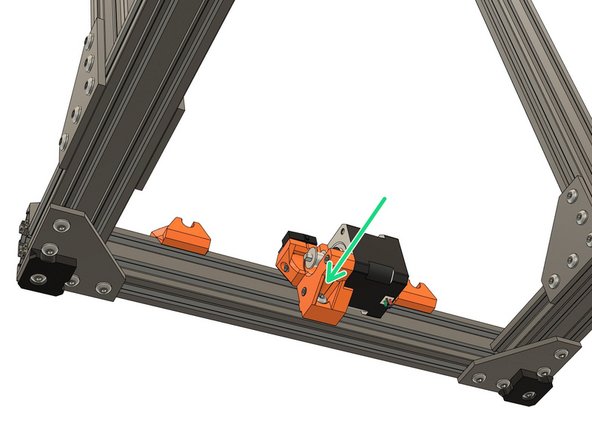

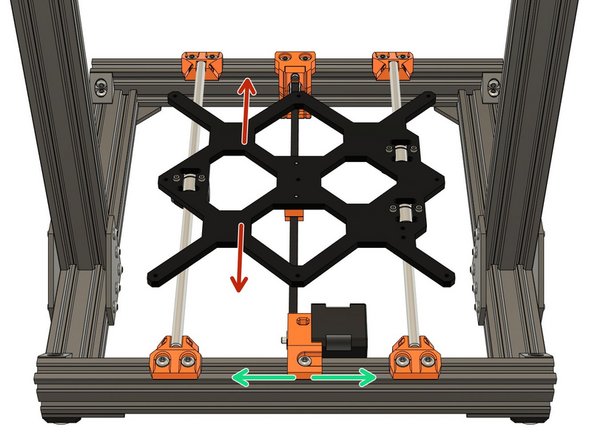

Place the Y motor on the y_motor_mount as shown on the first image. The cables must be orientated downward.

-

Secure the motor with 3x M3x18 screws. Do not fully tighten them yet.

-

Whilst pushing in the direction shown, fully tighten all 3 screws.

-

Check that the motor cables are oriented correctly.

The tolerance on these holes as the part printed for me seemed to be maybe 10micron or so too tight (using extrusion multiplier calibrated prusament, which seems pretty consistent) for the m3 screws in the LDO kit. (Maybe some sort of slight layer shift?) I had to lightly clean them up with a noga triagular de-burring tool to avoid having to “self tap” the screws through but it was close enough I could have “tapped” the screws in if need be. I assume these bores are intended to be a tight fit to prevent the mount fro slipping? Should I have “self tapped” the screws in?

Those holes should not be threaded but smooth. You can drill them with an 3.1mm drill bit. Make sure to set the extrusion multiplier for every spool you are using. Even if they are from the same brand, type and color (because plastic might melt a little differently).

-

-

-

Install the y_motor_mount on the extrusions in the back. Do not fully tighten the screws. We will set the position in a later step.

-

1x M5x12 on top.

-

1x M5x16 on bottom.

-

Always tighten the y_motor_mount screws evenly, incrementally and in turn. This ensures that the motor mount is properly square on the extrusions.

Text should reference “Step 33 Y axis parts positionning - MK3(S)” , currently says Step 19. Also looks a typo in step 33 title.

Christopher Salinas - Resolved on Release Reply

-

-

-

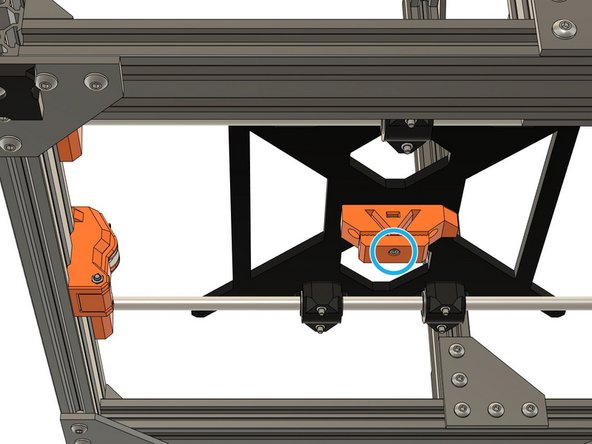

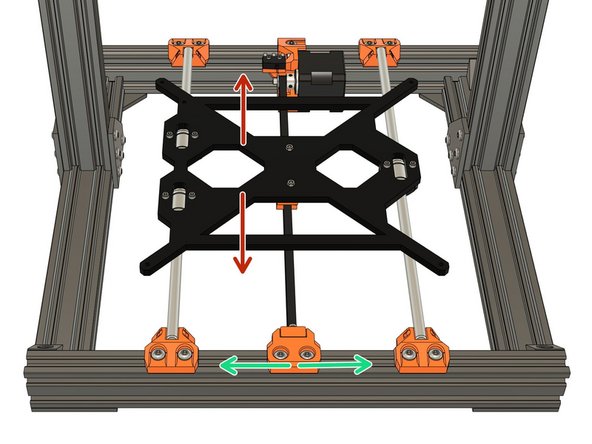

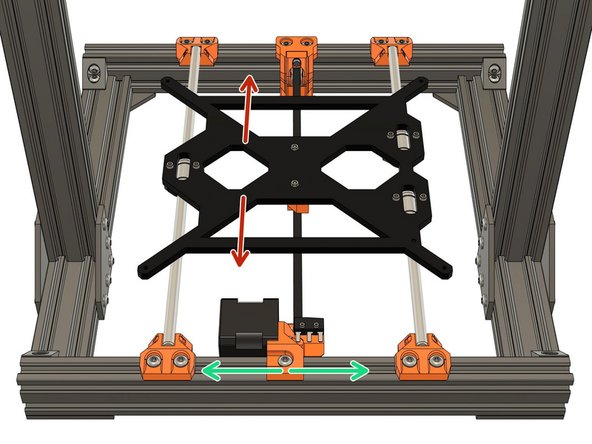

Take your time with this step. It is important that it is done correctly or it can cause issues later with your printer. Do not over-tighten the bearings or you may cause permanent damage to them.

-

Secure the bearing holders with 6x M3x25 screws. Do NOT tighten them yet!

-

Start tightening, evenly, incrementally and in turn. the M3x25 screws. While tightening, test if the bearing holder can rotate in the directions shown by the red arrows. When it no longer moves, in this direction, stop tightening immediately.

-

Check whether the bearings can slide along the slot.

-

If the bearing can slide: tighten evenly, incrementally and in turn, the M3x25 screws until you can't move it anymore. Do not over-tighten!

-

If the bearing is not moving anymore: continue to the next bearing.

-

Repeat this step for the two remaining bearings.

is it the inside of the bearing that should be tested for the rotation to determine the force applied with the screws? they still rotate around if fully tightened. Or is it the 45 degree angle rotation of the whole housing of the bearing inside the bearing holder that should be tested for rotation? It is not quite clear.

It is the bearing holder that should be tested for rotation. I have updated the description to make it clearer.

-

-

-

Gently insert 2x Y axis smooth rods (330mm long).

-

You must not use any significant force whilst inserting the rods into the linear bearings.

-

Don't rotate the smooth rods, the LM8UU bearings are not made to rotate.

-

Loosen the M5 screws of the 2x right y_rod_holders. You should be able to slide them easily by hand.

-

Clip the Y smooth rods and carriage assembly into the y_rod_holders. The Single bearing should be to the right.

-

It is very important to have the LM8UU bearings correctly oriented or you will have issues later in the assembly.

-

-

-

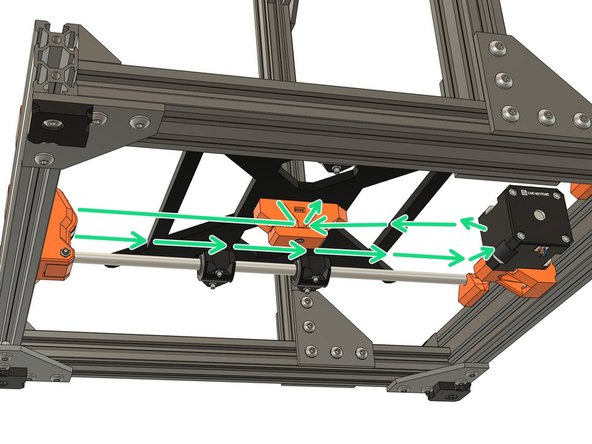

Take your time with this step.

-

Move the Y carriage, backwards and forwards along the whole length of the Y axis, at least 6 times. This will align the right smooth rod (single LM8UU side).

-

Move the Y carriage to the front and tighten the right-front y_rod_holder incrementally.

-

Move the Y carriage to the back and tighten the screws for the right-back y_rod_holder evenly, incrementally and in turn.

-

Never use the build_helper_y with the right smooth rod, it is made to align left smooth rod only (dual LM8UU side).

-

Tech tip: If you have a 200mm caliper you can measure the distance from the smooth rods directly on the metal. The spacing of the smooth rods is 170mm, the diameter of smooth rods is 8mm, which means the external spacing you should measure will be 170 + 2*8/2 = 178mm.

-

-

-

Set the y_idler_mount and y_motor_mount position as following:

-

51mm for the y_idler_mount.

-

48mm for the y_motor_mount.

-

We will adjust these positions, if necessary, after the belt is in place and tensioned.

Are these measurements from the very front of the Y-rod holders and idler/motor mounts, or are they between the square (not angled) parts of the mounts?

Matthew Van Zante - Resolved on Release Reply

from the flat side/middle of the parts. The exact measure aren’t critical as you will adjust later when everything is assembled.

-

-

-

Install the y_belt_holder under the Y carriage with 2x M3x10 (reused from your original Prusa). The grooves should face the dual bearings side.

-

Verify the orientation of the y_belt_holder.

Didn’t think about this while building as I get reall focused on the instructions I am currently on, but why don’t we install the y_belt_holder before adding the rods in the bearing?

That is a good point, would be easier I agree, I think I did it like that because it is needed to be done like that for MK2(S)/2.5(S).

-

-

-

Remove the M3x25 screw, used during installation, from the y_idler_mount and add a washer to the screw.

-

Insert the y_idler_tensioner into the y_idler_mount and reinsert the M3x25 screw with its washer.

-

Insert an M3 locknut into the left side of the y_idler_mount and thread an M3x30 screw from the other side. Use this screw to help seat locknut correctly, in the part. Do not over-tighten this screw, the y_idler_tensioner should move with almost no resistance.

-

Confirm you have a washer on the M3x25 tensioning screw.

-

Check that the y_idler_tensioner can move with almost no resistance.

Additionally, the y_idler_mount could be redesigned in a way that it takes the same M5x12 screws as the rod holders to mount them (instead of the M5x10). Thus the BOM would be reduced and assembly simplified.

Schrödingers Cat - Resolved on Release Reply

While all my other 3D printed parts fitted perfectly my y_idler_mount broke apart around the inserted M3 locknut. My parts were printed with Prusament PETG using the specific profiles from PrusaSlicer incl. flow and step calibration.

Schrödingers Cat - Resolved on Release Reply

I have seen this problems once too, I have an improved version in the work to reinforce this section.

This washer, I don’t see this on the BOM and MK3S didn’t ship with them either. Is this something I missed?

That was missing in the BOM, sorry for that and now fixed. Official kits have the washer and if this is not the case you can contact the distributor.

-

-

-

Unscrew the idler tensioner screw until there is a small gap (about 3mm).

-

Unscrew the clamp of the y_belt_holder to help the insertion of the belt in the next step.

-

-

-

Insert the top section of the belt into the left side of the y_belt_holder. If necessary, use a small slotted screwdriver to help insert the belt. The belt should be inserted to the full depth of the groove .

-

Make sure the belt teeth are correctly oriented according to the shape of the y_belt_holder.

-

Continue to route the belt around the Y motor pulley and finish by inserting the belt into the y_belt_holder. The belt should have almost no tension, it will be adjusted later.

-

If the belt is too long to fit inside the y_belt_holder you can trim the excess.

-

Verify that the belt is fully inserted into the slot.

-

Tighten the M3x18 screw to secure the belt.

The step where the zip ties are mounted to hold the rods in place should come first so that the machine can be flipped over to mount the belt.

Schrödingers Cat - Resolved on Release Reply

The clipping of the smooth rods is strong enough, you can flip the printer. I have decided to put them at the end in case smooth rods needs to be removed for any type of reason.

-

-

-

Apply a light tension to the belt to remove any slack. Do not over-tighten the belt or adjustments will be impossible.

-

We will adjust the belt, to the correct tension, in a later step.

-

Adjust the position of y_idler_mount and y_motor_mount using their M5 screws. Try to have the belt riding centered as best as possible on the pulley (motor side) and the idler (tensioner side).

-

It is important to move the Y carriage back and forth along the whole axis between each adjustment.

-

Remember that when you tighten the y_idler_mount and y_motor_mount screws you must do so evenly, incrementally and in turn. If you don't do this you may cause those parts to be misaligned.

-

-

-

Secure the Y smooth rods with 4 zip ties. Note the orientation of them.

-

-

-

Congratulations you have finished this chapter :)

-

Go to the next chapter: 06. Z axis motion

-

Cancel: I did not complete this guide.

40 other people completed this guide.

2 Comments

@gregsaun I can translate the manual into Polish lang.

How can I do this and did you provide for this possibility.

Cyryl Sochacki - Resolved on Release Reply

Hi, thank you for proposing your help. Unfortunately, I don’t have time right now and to be honest I don’t know how it works with Dozuki

This should be 8x M5x10 screws, otherwise the screws hit the extrusion and the rod holders can’t be tightened. I don’t think this is just an issue with the MK2.5S rod holders… I think we use the same part in both sets.

Michael Ratcliffe - Resolved on Release Reply

If you are using an early shorter frame (with the extrusion length at 311mm as explained here: https://github.com/gregsaun/prusa_i3_bea... ) then yes you need to use the M5x10mm screws.

Grégoire Saunier -